Technical Column

The Logic Behind the Shape and Size of Anechoic Chambers

Jul 16, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- The Logic Behind the Shape and Size of Anechoic Chambers

Acoustic Power Measurement

HBK × Sonora Delivering the Ideal Acoustic Test Environment

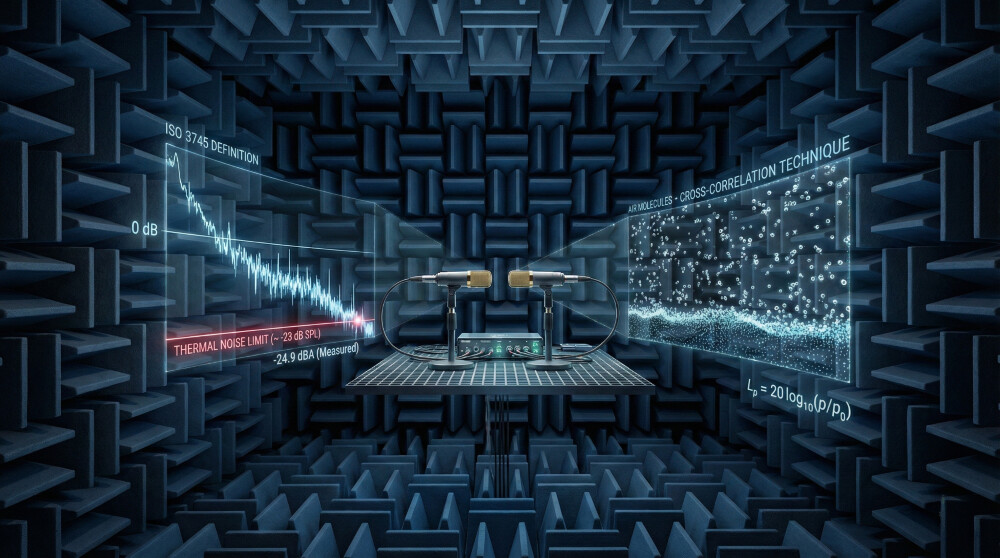

Anechoic chambers are artificial environments designed to eliminate sound reflections and recreate a true free-field condition. For precise measurements of sound power, sound pressure, or frequency response, this free-field must be accurately established.

However, achieving a theoretical free-field requires more than just a “soundproof room” or simple “absorbing materials.”

In this article, we explore—through the lens of HBK’s measurement technology and Sonora’s acoustic design expertise—why anechoic chambers are built as rectangular boxes, and why there are limits to the measurable area within the chamber.

Why Are Anechoic Chambers Rectangular?

The Acoustic Logic Behind the Shape

The primary reason for choosing a rectangular shape over a square one in anechoic chamber design is to suppress standing waves.

In square rooms, equal wall distances make sound reflections more likely to overlap, which often results in specific frequencies forming standing waves. This disrupts the uniform sound field and introduces errors into measurements.

In contrast, rectangular designs deliberately offset the wall distances, preventing such overlap and maintaining acoustic randomness in the space. HBK’s acoustic testing guidelines and ISO 3745:2012 emphasize the importance of distance and angular distribution of microphones, further reinforcing the superiority of the rectangular layout.

* Sonora Design Insight

To ensure inverse square law conditions, Sonora conducts comprehensive simulations of reflections and interference based on the room geometry and absorber layout. This leads to optimized room shapes and ideal free-field zones.

Why Are Measurable Areas Limited?

Designing for Where the Inverse Square Law Holds True

In anechoic chambers, the inverse square law must apply—meaning sound pressure should decay by approximately 6 dB for each doubling of distance from the source. However, in certain situations, this law breaks down:

- Too close to the sound source (near field)

- Too close to chamber walls or floor

- Sources that are not point-like

To address these challenges, HBK recommends managing the K2 environmental correction factor, a quantitative method for evaluating deviations from the ideal sound field. Using tools such as the Type 4204 reference sound source and Sound Power Software, engineers can verify that the anechoic space performs within ISO tolerance limits.

HBK Solutions in Practice

| OmniPower™ Sound Source Type 4292-L | Ideal for ISO 3744/3745-compliant field verification |

|---|---|

| Sound Power Software with PULSE System | Automatically collects and analyzes microphone data, applying K1/K2 corrections to ensure accurate sound power evaluation |

Sonora’s BF Series: Ensuring Free-Field with Advanced Absorption

Conventional glass wool wedges offer high performance but come with issues like dust and material degradation. Sonora has developed the BF Series (Broadband Fractal) to solve these challenges:

| BFW (Broadband Fractal Wedge) | Reduces sound reflectance significantly, delivering strong absorption even below the cut-off frequency |

|---|---|

| BFB & BFP | Tailored for walls, ceilings, and floors; modular design enhances both flexibility and maintainability |

These materials, when used alongside HBK’s OmniPower source, allow the chamber to consistently meet even strict ISO targets like K2 ≤ 0.5 dB.

Sonora × HBK: Total Acoustic Evaluation Solutions

By combining HBK’s precision instrumentation with Sonora’s acoustic design and construction, we offer a complete solution—from chamber layout to calibration, validation, and ongoing measurements.

Conclusion

Every aspect of an anechoic chamber—its shape and its measurable area—is based on solid acoustic theory and practical validation. HBK and Sonora combine global standard compliance with original technology to deliver acoustic environments that are not only accurate but also maintainable and future-proof.

Accurate measurement starts with precise design.

Discover how HBK and Sonora’s total solutions can elevate your acoustic evaluations.

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.