Technical Column

Acoustic BOX Integration with HBK PULSE — Quiet Test Environments for Fully Automated Acoustic Inspection —

Aug 11, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Acoustic BOX Integration with HBK PULSE — Quiet Test Environments for Fully Automated Acoustic Inspection —

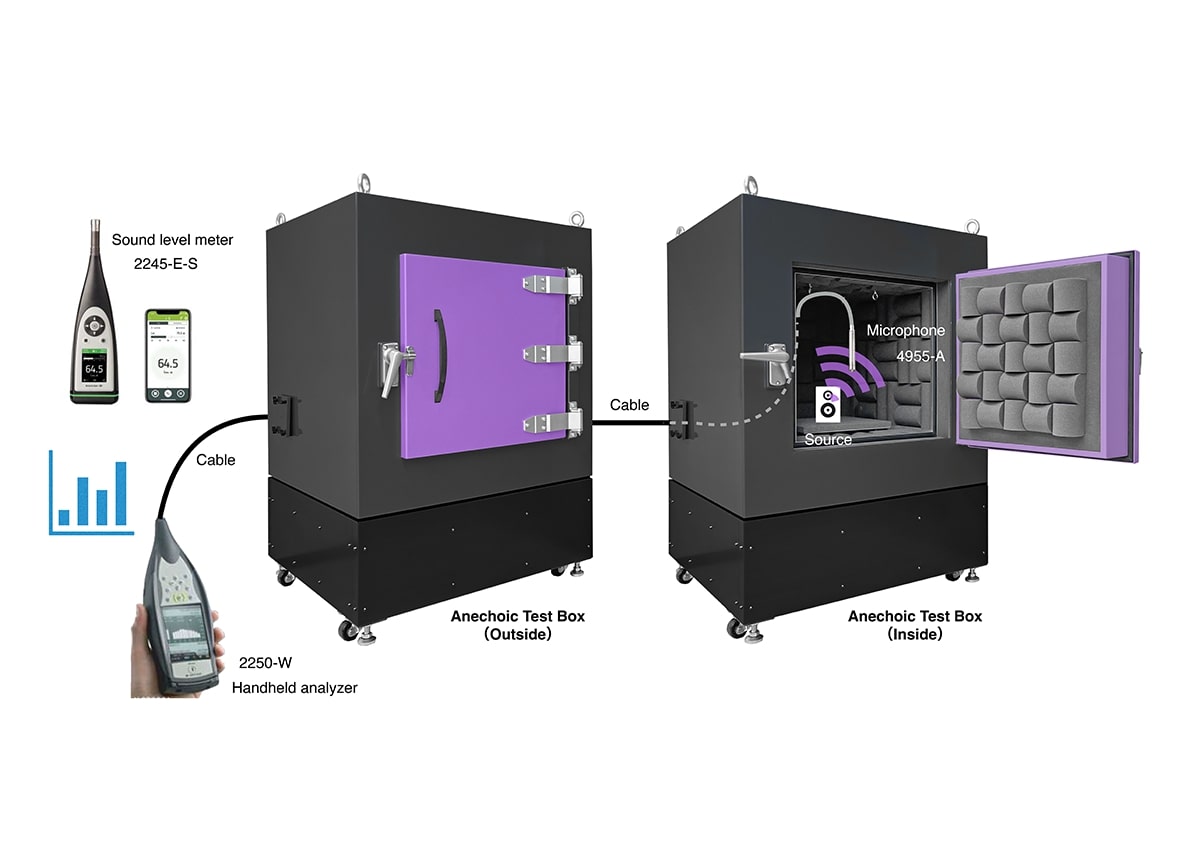

Simplified Performance Testing Using Anechoic Box + Sound Level Meter

Introduction: Automation Requires Environmental Control

Automated testing for speakers, microphones, and communication modules is growing rapidly.

However, these systems often encounter uncontrollable variables such as:

- Environmental noise

- Reflections in the test space

- Inconsistent microphone placement

At Moritani, we solve these challenges by combining HBK’s PULSE acoustic analysis system with the Anechoic Box (AEB) developed by Sonora Technology.

The result: a complete solution for automated, accurate, and repeatable acoustic testing.

3 Essential Conditions for Reliable Acoustic Test Lines

| 1. Noise-Isolated Space | The enclosure must block external sound and suppress internal reflections. |

|---|---|

| 2. Integration with Automated Systems | The structure must accommodate conveyors, robots, and EOL lines. |

| 3. Stable & Repeatable Measurement Setup | Microphone positioning, sensor stability, and analysis consistency are critical. |

The combination of HBK PULSE + Sonora AEB satisfies all of these.

Typical System Configuration: AEB + PULSE

Here is a proven configuration for high-volume testing:

| Component | Function |

|---|---|

| AEB (Anechoic Box) | Free-field environment using sound-absorbing walls, high sound isolation, customizable structure |

| Microphone | HBK high-sensitivity free-field microphone, selected per DUT type |

| PULSE | FFT analysis, automatic OK/NG judgment, waveform visualization |

| Interface | Integration with PLC, robots, and automated test flow |

This system enables pass/fail judgments within seconds, with full traceability and data logging.

Applications in the Field

- Smart speaker production line testing (speaker/mic functions)

- Portable transceiver noise and abnormal sound detection

- Power tool & small motor acoustic fingerprinting

- Communication module voice-response validation (Siri/Alexa/VoIP)

The AEB structure is fully customizable for:

→ Size, opening mechanism, DUT fixtures, and inline integration.

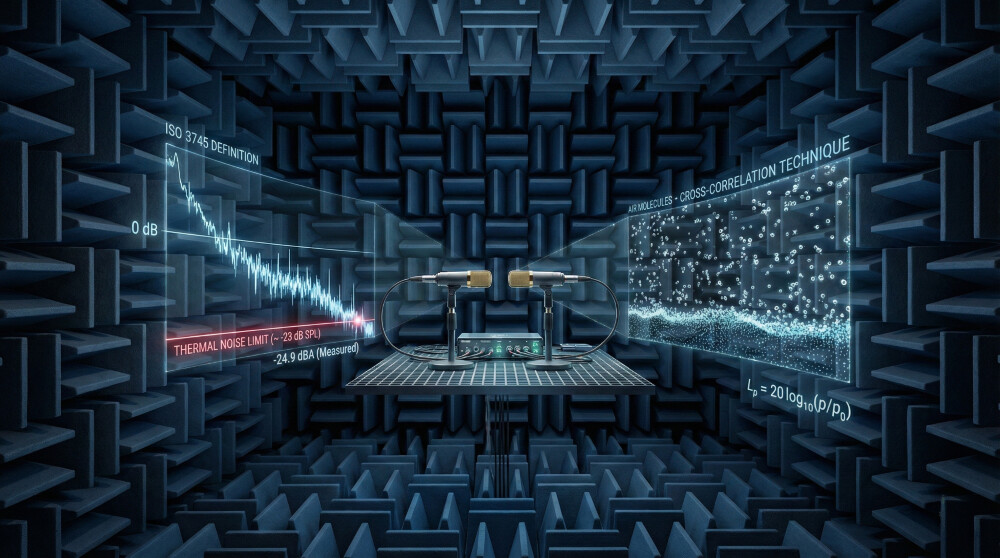

Why Acoustic Performance Starts with the Box

Even with PULSE’s powerful analytical features, a poor test environment degrades your data.

Sonora’s AEB provides a stable, repeatable, and quiet space to allow HBK sensors to perform at their best.

It’s not just about silence — it’s about repeatability, stability, and real-world reliability.

That’s why leading manufacturers trust the AEB as the heart of their automated inspection systems.

Consult Moritani for Custom Solutions

- Planning to automate end-of-line acoustic inspection?

- Need a quiet test cell integrated with HBK PULSE?

- Looking to customize AEB structure for your production line?

- Need help selecting HBK microphones or sensors?

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.