Technical Column

Efficient Acoustic Testing for Compact Electric Devices — EAAC × HBK Analysis Enables Fast, Reliable Mass Production Checks —

Sep 10, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Efficient Acoustic Testing for Compact Electric Devices — EAAC × HBK Analysis Enables Fast, Reliable Mass Production Checks —

Electroacoustic Measurement

Introduction: Small Devices, Big Challenges in Acoustic Testing

As smart appliances, small fans, pumps, and electric modules become more widespread, low-noise performance has become a key quality indicator.

But testing compact devices acoustically poses a dilemma:

- Output levels are low

- Structures are complex

- Inspection needs to be fast and automated

Precision and speed rarely go hand in hand—unless the environment and instruments are built for it.

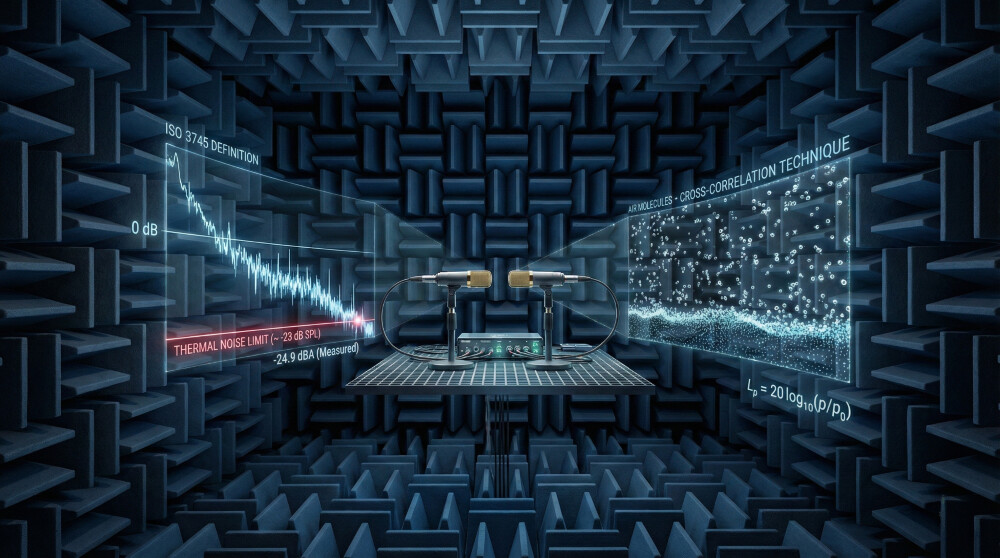

Solution: EAAC × HBK for High-Speed, Noise-Free Testing

At Moritani, we deliver optimized setups using:

Test Environment

EAAC (Electroacoustic Anechoic Chamber)

Compact, quiet, reflection-free environment for clean measurements

Sensors & Analysis

HBK Microphones × PULSE System

FFT analysis, NG thresholds by frequency band, automated judgment logic

Automation Options

- Automatic chamber doors

- Robotic DUT loading

- Complete cycle: signal generation → measurement → pass/fail output

Workflow Example: Inline Testing for Portable Pumps

- 1. Device is automatically loaded into EAAC from conveyor

- 2. HBK microphone captures operational sound

- 3. FFT data is compared against a stored reference spectrum

- 4. PULSE outputs OK/NG result to PLC → sorting mechanism handles it

The entire cycle takes only 3–5 seconds, enabling real-time judgment with no offline processing.

Why EAAC Is Ideal for Compact DUTs

- Even in 1–2 m² space, true free-field conditions are achieved

- Easy to install and relocate—perfect for flexible line expansion

- Designed for acoustic compatibility with HBK sensors

For small devices, even minor reflections or ambient noise can distort results. EAAC offers the environmental stability needed for precision.

Customization Options Available

- Custom chamber dimensions for your DUT size

- Acoustic layout optimized for your target frequency range

- Integrated automation and pass/fail interfaces

- Full integration support with HBK microphones and analyzers

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.