Technical Column

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement —

Nov 18, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement —

Acoustic Power Measurement

Introduction

Precision in acoustic testing depends not only on instruments, but on the stability of the environment in which they operate.

Reproducibility — the ability to obtain identical results under identical conditions — is the true foundation of reliable measurement.

This article explores how temperature, humidity, vibration, airflow, and electrical noise affect results, and how to design environments that ensure stability.

Why Reproducibility Matters Most

In acoustics, environmental fluctuations can distort results more than the test object itself.

Examples include:

- Speed-of-sound variations with temperature

- Absorption changes with humidity

- S/N degradation from background noise

- Positioning shifts altering pressure fields

Reproducibility means more than repeating a test;

it means engineering stability into the space.

Key Environmental Factors

| Factor | Effect on Measurement | Control Strategy |

|---|---|---|

| Temperature | Shifts in sound velocity | Climate control and compensation |

| Humidity | Alters absorption and damping | Dehumidifiers/humidifiers, material selection |

| Airflow | Causes turbulence and standing waves | Diffused outlets, low-speed ventilation |

| Vibration | Mechanical coupling to sensors | Floating floors, isolation mounts |

| Electromagnetic noise | Signal distortion and interference | Shielding, grounding, filtering |

All must be addressed as an integrated control system.

Temperature and Humidity Management

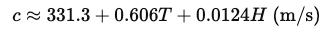

The speed of sound varies as:

Even ±1°C or ±5%RH deviations affect phase and level precision.

Stable rooms maintain:

- ±1°C temperature and ±5%RH humidity

- Air velocity below 0.05 m/s

- Gentle air circulation through absorber arrays

These ensure consistent propagation conditions.

Vibration and Structural Resonance Control

Low-frequency vibration (20–200 Hz) can invalidate results.

Countermeasures include:

- Independent vibration-isolated foundations

- Floating floor frames

- Mechanical decoupling of DUT and equipment

- Isolation of HVAC and external machinery

These create structural silence—a mechanically quiet foundation for testing.

Background and Electrical Noise Management

Acoustic accuracy requires both acoustic and electronic quietness.

Key practices:

- Dedicated, grounded power lines for audio equipment

- Shielded, twisted microphone cabling

- RF-shielded chamber walls

- Synchronized digital clocks for signal acquisition

A noise-free environment is a prerequisite for repeatable data.

Engineering Environmental Stability

Reproducibility must be designed, not assumed.

- Continuously monitor environmental parameters

- Integrate acoustic, mechanical, and electrical systems in design

- Maintain traceable environmental records for all measurements

This transforms test results into verifiable, comparable data over time.

Conclusion: Stability Defines Trust

Silence is not the absence of sound—it is the presence of stability.

Reliable acoustic measurement begins with an environment that stays constant even as the world around it changes.

Designing that stability is how reproducibility is built.

Latest Posts in Technical Column

-

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight— -

2025.10.20

End-of-Line Acoustic Testing — Quantifying Quietness in Mass Production —

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.