Technical Column

Measuring Silence: How Anechoic Chambers Support Industrial Quality

Nov 25, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Measuring Silence: How Anechoic Chambers Support Industrial Quality

Acoustic Power Measurement

Introduction

Quietness can’t be claimed—it must be measured.

In modern industry, acoustic performance is a quantifiable element of product quality.

At the center of that precision lies the anechoic chamber.

This article explores how anechoic environments make it possible to evaluate, design, and sustain silence as an industrial standard.

What Is an Anechoic Chamber?

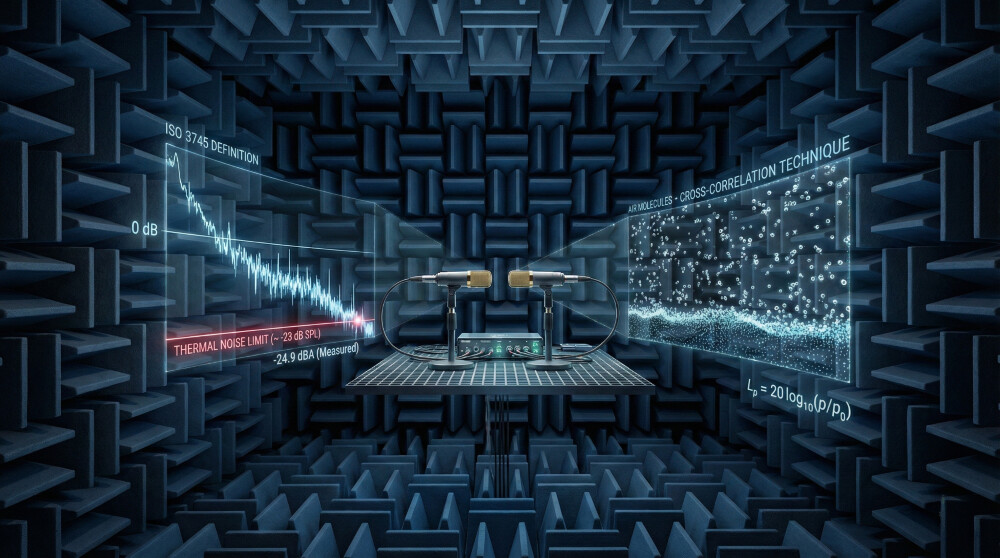

An anechoic chamber is a room where sound reflections are minimized from all surfaces—walls, ceiling, and floor—creating a near free-field condition.

This allows precise measurement of sound power, frequency response, and directivity for devices such as speakers, motors, and fans.

| Type | Application |

|---|---|

| Fully Anechoic Chamber (FAC) | Acoustic & electroacoustic testing |

| Semi-Anechoic Chamber (SAC) | Automotive & machinery noise tests |

| Electroacoustic Chamber (EAAC) | Microphone & speaker testing |

| Sound Power Chamber (SPAC) | ISO/JIS sound power measurements |

Anechoic chambers are the measurement counterpart to soundproofing design—where silence is not just created, but verified.

The Industrial Importance of Measurement Environments

In industrial design, sound is a metric of quality:

- In consumer electronics: quietness defines user perception

- In automotive: sound spectrum affects brand identity

- In precision manufacturing: noise affects measurement accuracy

Only a controlled and repeatable test environment ensures consistency.

The anechoic chamber provides that standard.

Key Performance Requirements

An effective anechoic chamber must deliver:

- 1. High absorption down to low frequencies

- 2. External noise isolation with soundproof structures

- 3. Vibration control for accurate readings

- 4. Quiet operation of HVAC and lighting systems

The integration of these factors defines a true “measurement-grade” silent room.

The Role of the BF Series

The BF Series (Broadband Fractal Series) provides broadband, durable, and cleanable sound absorption—essential for modern test rooms and semi-anechoic facilities.

Its advantages include:

- Stable absorption over a wide frequency range

- Dust-free, low-maintenance surfaces

- Consistent performance in varying humidity and temperature

These features make it an ideal solution for maintaining long-term precision and cleanliness in acoustic test environments.

From Measurement to Design

Anechoic chambers are evolving beyond testing.

They are now used for sound design and tuning, where products are engineered not only to be quiet but to sound right.

Applications include:

- Psychoacoustic evaluation

- AI-based acoustic simulations

- Automated sound inspection for quality assurance

Silence is becoming not just a condition to measure—but a design parameter in itself.

Conclusion: Creating, Measuring, and Sustaining Silence

Soundproofing designs create silence.

Anechoic chambers measure it.

And with durable materials like the BF Series, that silence can be sustained.

In the modern industry, quietness is more than absence of noise—it’s a measurable, maintainable element of quality.

And the anechoic chamber remains its most trusted instrument.

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.