Introduction to Our Solutions

VSAC + Pass-by System and Related Products

- HBK × SONORA Acoustic Measurement Solution Official Website

- Introduction to Our Solutions

- VSAC + Pass-by System and Related Products

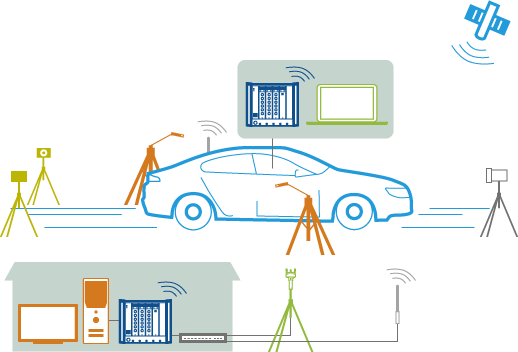

Pass-by noise refers to the sound generated by a vehicle while it is in motion. We offer a range of measurement solutions for pass-by noise, both in indoor and outdoor environments.

Indoor Pass-by Noise Measurement System

Pass-by noise testing can be conducted indoors using a VSAC (Vehicle Semi-Anechoic Chamber).

Note: VSAC = Vehicle Semi-Anechoic Chamber

Since 2019, indoor pass-by testing has been approved for both type approval (R51.03 Amendment 4) and conformity of production. Measuring exterior vehicle noise using a chassis dynamometer installed in a large indoor semi-anechoic chamber is significantly more convenient. The controlled environment protects against weather conditions, ensures high repeatability, and allows for measurements year-round, 24/7.

Just like outdoor pass-by noise testing, the vehicle is operated on a stationary dynamometer while microphone arrays are positioned on both sides to measure the emitted sound. The microphone signals are processed along with vehicle speed data, including Doppler correction, to produce results directly comparable to those from outdoor measurements. The standard also provides methods for correcting tire noise using outdoor measurement data obtained on an ISO test track.

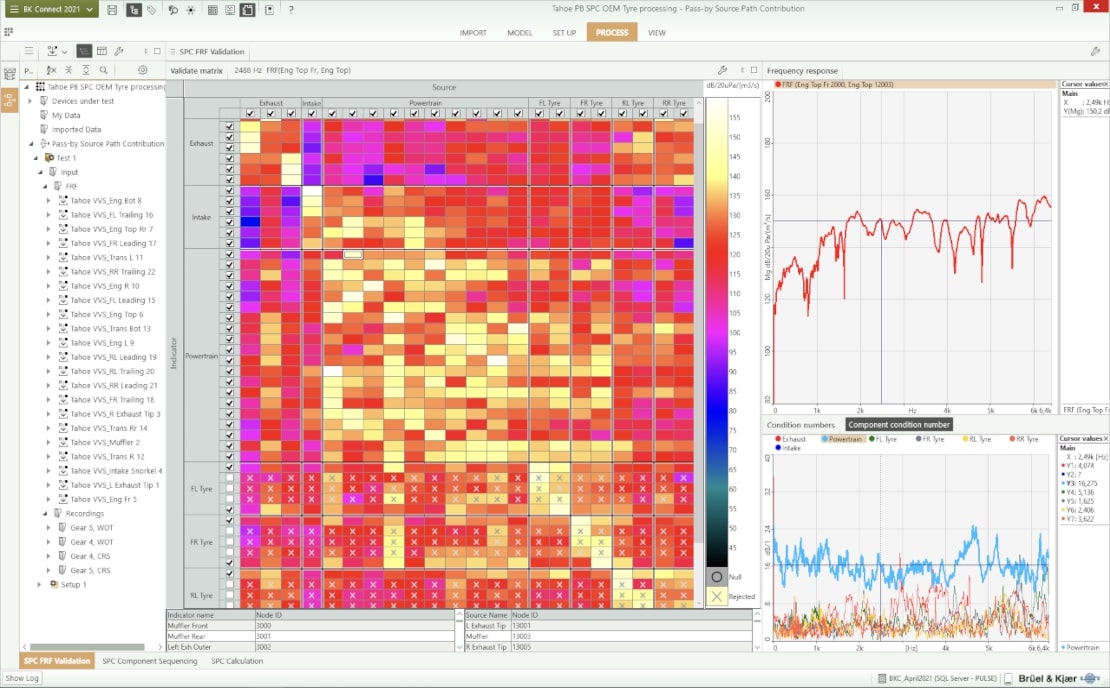

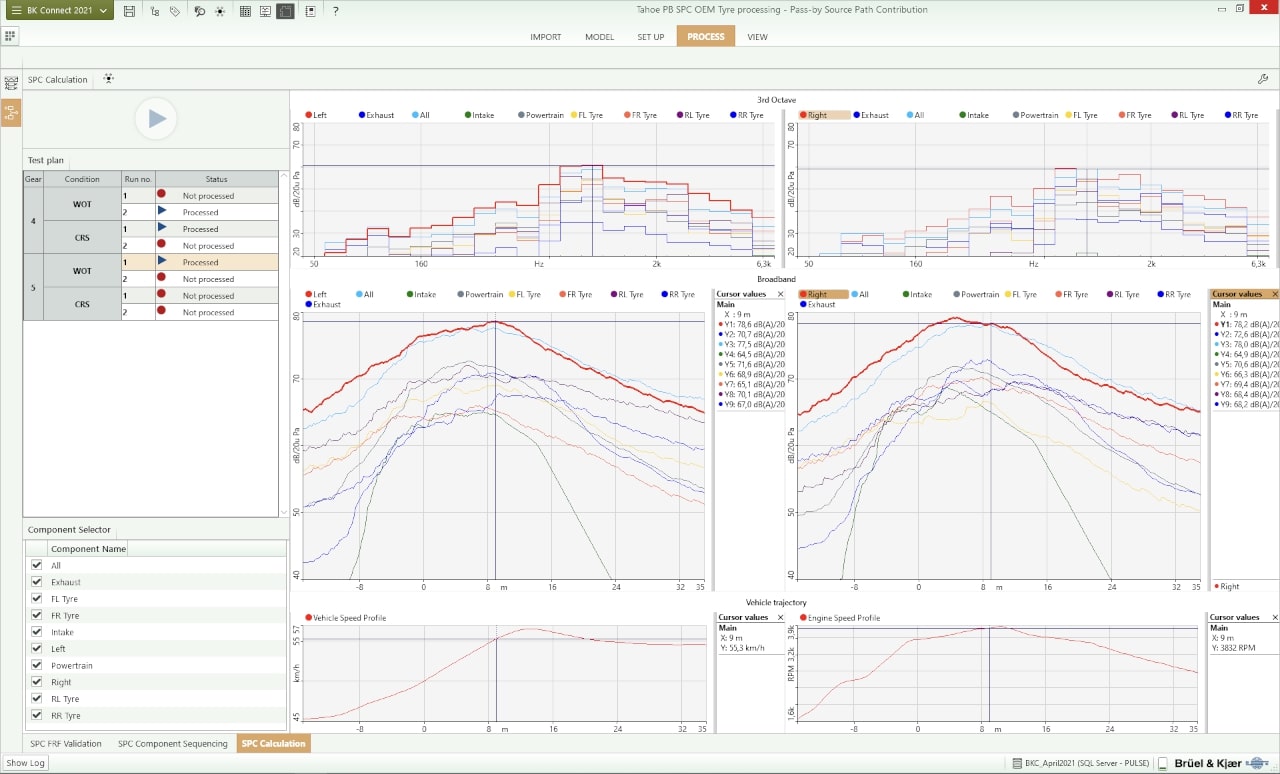

Pass-by SPC (Sound Path Contribution Analysis)

Pass-by SPC (Sound Path Contribution) analyzes how various noise sources—such as tires, engine/motor, and exhaust—contribute to the overall pass-by noise.

Source Path Contribution (SPC) is a technique used to evaluate the contribution of suspected noise or vibration sources through various acoustic and vibration paths to a specified receiver position. By focusing on dominant sources, engineering efforts can be directed toward the areas with the greatest impact.

While SPC is commonly used in interior noise analysis—where both sources and paths involve acoustics and vibrations—BK Connect Pass-by SPC is specifically designed for acoustic analysis using data acquired from indoor pass-by test setups.

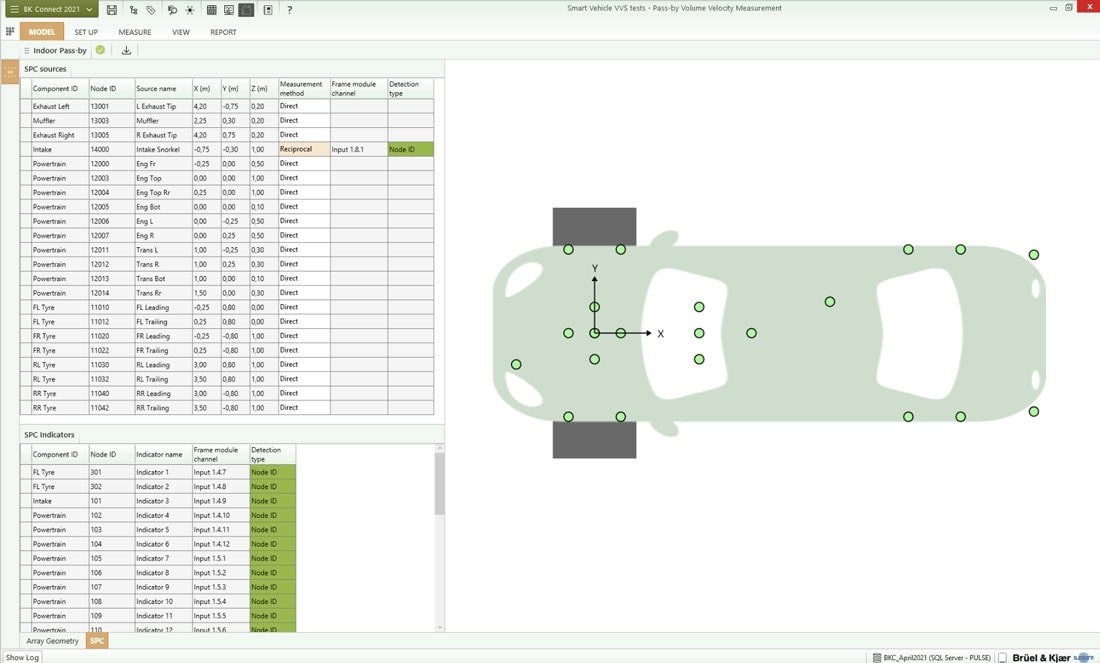

Volume Velocity Source Measurement

Volume Velocity Source Measurement Software (part of BK Connect) is designed for the measurement of acoustic transfer functions.

A Volume Velocity Source (VVS) is typically used to measure Acoustic Transfer Functions (ATFs) relevant to sound source contribution analysis. HBK’s VVS system employs a specialized dual-microphone probe to directly and accurately measure volume velocity in real time.

The Volume Velocity Source Measurement Software is designed to work seamlessly with the VVS system. It ensures precise results by guiding the measurement process based on a preloaded test plan, enabling fast and efficient high-accuracy ATF measurements.

Outdoor Pass-by Noise Measurement System

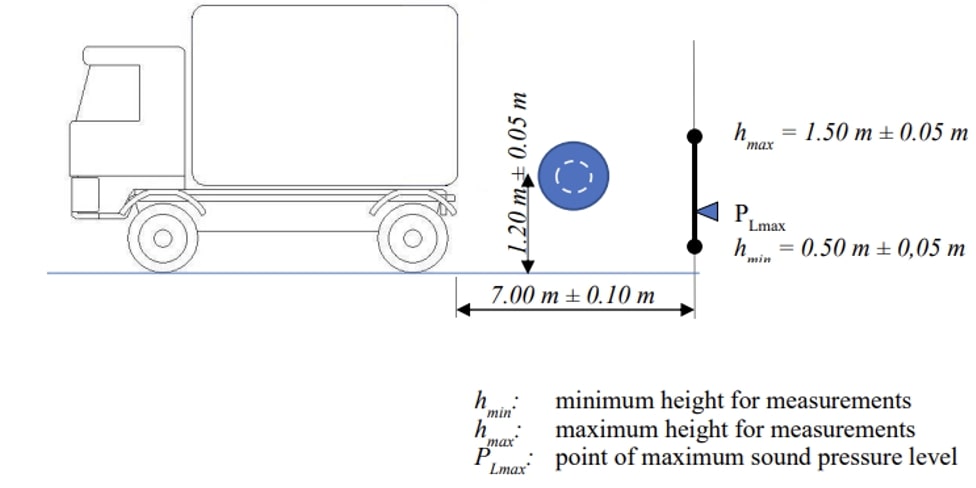

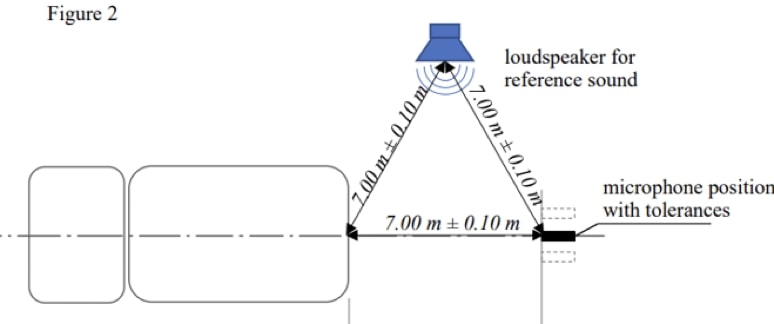

Enables outdoor pass-by noise testing in compliance with ISO standard requirements.

Applicable Standards

- Pass-by noise testing for M-category (light vehicles) and N-category (trucks) road vehicles in compliance with ISO 362:1998 and ISO 362-1:2012

- Pass-by noise testing for L-category vehicles (motorcycles) in compliance with ISO 362-2:2012

- Exterior noise measurement in compliance with ISO 3325 (tires) and ISO 5130 (exhaust noise)

- Compliance with regulatory standards based on ISO test procedures, including:

- UN/ECE R51.03 (Noise emission of M and N category vehicles)

- UN/ECE R41.04 (Noise emission of L category vehicles, e.g. motorcycles)

- UN/ECE R117 (Tire noise)

Vehicle Noise Testing: Applications

Compliance with R165 Regulation for Reversing Alarm Sound Measurement

Proximity Exhaust Noise and Horn Sound Testing

VSAC + Sound Level Meter 2245

Wireless Control via Type 2245 Mobile Application

With the Type 2245 Sound Level Meter, remote operation can be performed from a location away from the specific receiving point.

By utilizing Wi-Fi-based wireless control, there is no need to connect cables from the microphone inside the semi-anechoic chamber to the outside.

This eliminates the influence of ambient noise caused by human activity within the chamber, ensuring a more accurate low-noise environment for measurement.

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.