Technical Column

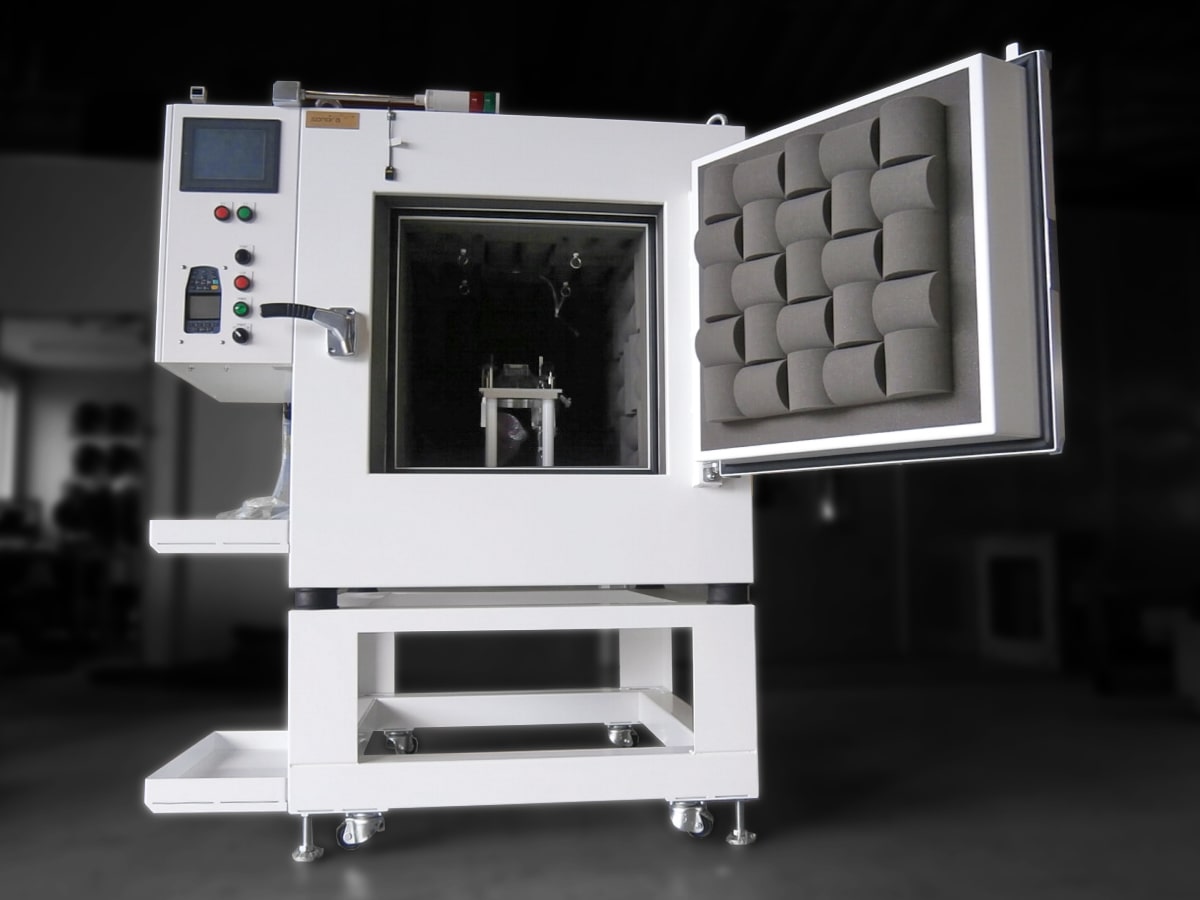

Anechoic Box for Abnormal Noise Inspection (Sound Level Meter + Anechoic Box)

May 26, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Anechoic Box for Abnormal Noise Inspection (Sound Level Meter + Anechoic Box)

Simplified Performance Testing Using Anechoic Box + Sound Level Meter

This anechoic box integrates a sound level meter, signal tower, control panel, and door limit switch into a single unit.

The inspection object is placed inside the box, and acoustic measurement is initiated via a push-button operation.

If the measured noise level exceeds the pre-defined threshold (e.g., due to abnormal noise), the system triggers the signal tower to light up, alerting the user.

All components are pre-installed at the factory, allowing users to operate the unit immediately after installation—no on-site integration is required.

While this model assumes manual loading of the test object, it can also be adapted for inline use with automated doors for loading and unloading products.

The image below shows a fully enclosed acoustic test chamber designed for 100% abnormal noise inspection in a production setting.

At Sonora Technology, we can develop and propose customized acoustic measurement systems, including both measurement instruments and enclosure design, from the ground up to meet your specific needs.

Latest Posts in Technical Column

-

2026.01.29

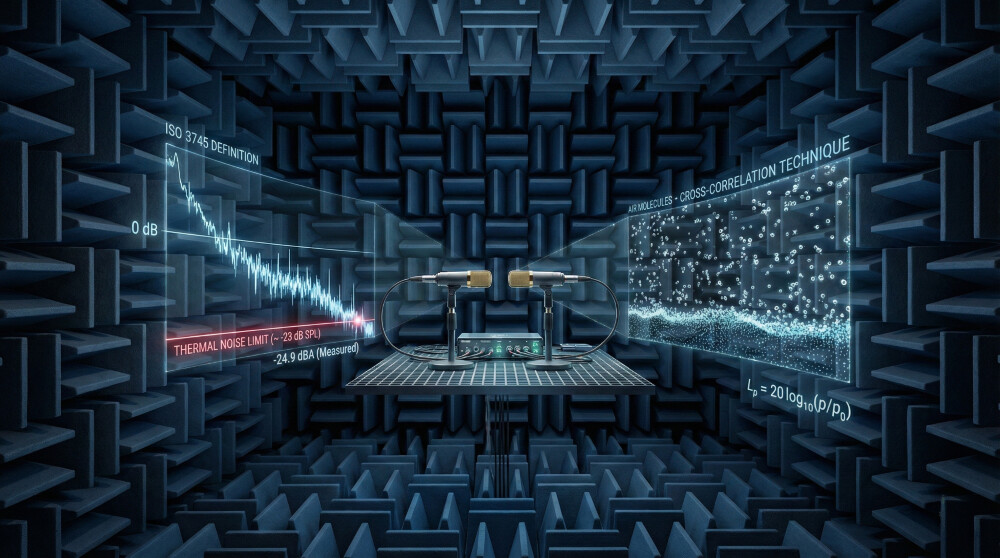

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.