Technical Column

Automated Acoustic Testing for Wireless Communication Modules — AEB × HBK System for Bluetooth Mics, Headsets, and Voice Devices —

Sep 15, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Automated Acoustic Testing for Wireless Communication Modules — AEB × HBK System for Bluetooth Mics, Headsets, and Voice Devices —

Simplified Performance Testing Using Anechoic Box + Sound Level Meter

Introduction: Ensuring Output and Input Quality in Voice Devices

Wireless microphones, Bluetooth speakers, intercom modules—these voice-related products all require acoustic performance verification at shipment.

However, their wireless nature introduces unique challenges that make traditional wired acoustic testing impractical.

Common Issues in Wireless Audio Product Testing

- 1. Noise intrusion and room reflections cause false readings

- 2. Microphone/speaker position shifts lead to unstable results

- 3. Signal delay or disconnection disrupts test repeatability

To overcome these, Moritani offers an integrated system using AEB (Anechoic Box) + HBK instruments + communication control modules for fully automated acoustic testing.

System Configuration: AEB × HBK × Communication Controller

| Component | Function |

|---|---|

| Acoustic Environment | AEB (Anechoic Box): Small free-field enclosure with high sound isolation |

| Source | HBK calibrated speaker: Sends test signals to DUT microphones |

| Microphone | HBK Free-Field Mic: Captures DUT speaker output |

| Control Interface | Bluetooth command triggers, signal routing, loopback checks |

All data is analyzed in real-time using PULSE software, enabling live FFT monitoring and pass/fail judgment logic.

Use Cases

| Bluetooth microphone | TX/RX acoustic validation |

|---|---|

| Wireless earbuds | Left/right channel balance & internal noise analysis |

| Headsets | Full duplex call quality testing (distortion, delay, noise) |

| Smart intercom modules | Voice command recognition and response loop testing |

Why AEB Is the Right Choice

- Isolated environment ensures only transmitted audio is measured

- Free-field design absorbs minor alignment variation

- HBK integration allows automated, logged OK/NG judgments

Combined with a proper trigger and Bluetooth controller, wireless testing becomes as stable as wired inspection.

Customization and Consultation

- Tailored AEB designs for wireless modules

- HBK speaker/mic setup optimization based on product specs

- Trigger control and loopback integration support

- Mass production line and development lab deployment

Latest Posts in Technical Column

-

2026.01.29

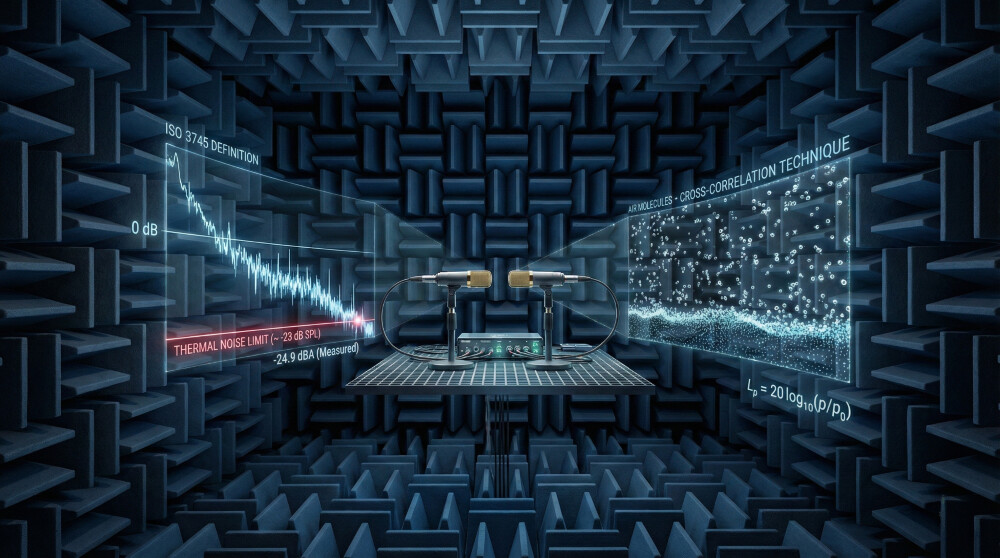

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.