Technical Column

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Oct 25, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Acoustic Power Measurement

Introduction

Modern acoustic and vibration testing generates massive amounts of data thanks to high-resolution sensors and recording systems.

Yet many laboratories still face a fundamental issue — data fragmentation.

Acquisition, analysis, and reporting often occur in isolated tools, making it difficult to reproduce results or trace conditions.

This article explores how integrated data flow design can connect the entire process from front-end measurement to back-end insight.

The Problem of Disconnected Measurement Data

Typical challenges in test environments include:

- Raw data not transferred cleanly between systems

- Missing metadata such as speed, load, or temperature

- Results stored as PDFs without reusable data

- Simulation results isolated from real measurements

To solve this, measurement software must be treated as part of an interconnected data ecosystem, not as standalone instruments.

Architecture for End-to-End Integration

A modern acoustic–vibration measurement system can be divided into three layers:

| Layer | Role | Key Elements |

|---|---|---|

| Front-End | Data acquisition | Sensors, microphones, accelerometers, front-end devices |

| Processing | Signal analysis | FFT, CPB, time-domain, and statistical analysis |

| Back-End | Data management | Databases, cloud systems, automated reporting |

When connected seamlessly, data transitions from mere waveforms to interpretable knowledge.

Connecting Frequency, Time, and Statistical Analysis

Acoustic diagnostics require different analytical perspectives:

- Frequency-domain analysis (FFT, CPB) – identifies resonances and tonal noise

- Time-domain analysis – captures transients and impulse responses

- Statistical analysis – quantifies variability and repeatability

Running these in separate tools fragments context.

Integrated software allows unified analysis within a single database, maintaining consistency across test conditions.

Database Integration and Traceability

Long-term reliability demands structured data storage, not isolated files.

Key principles:

- Automatically record metadata such as settings and environmental parameters

- Tag results by test ID, batch, or product type

- Keep results as live data for re-analysis and recalculation

Such traceable databases enable reproducibility across R&D, testing, and production.

Hybrid Analysis: Bridging Simulation and Measurement

Hybrid acoustic analysis combines real-world test data with simulation-based CAE models on the same platform.

Overlaying frequency response functions (FRFs) with structural simulations reveals how design and physical phenomena align.

This forms the backbone of data-driven acoustic engineering.

Conclusion: From Measuring to Understanding

Measurement alone is not insight.

The true goal of testing is understanding behavior through connected data.

Integrated software transforms acoustic testing from a linear process into a knowledge network where every result builds upon the next.

We are moving from designing quietness to understanding quietness— and that evolution begins with an integrated data flow.

Latest Posts in Technical Column

-

2026.01.29

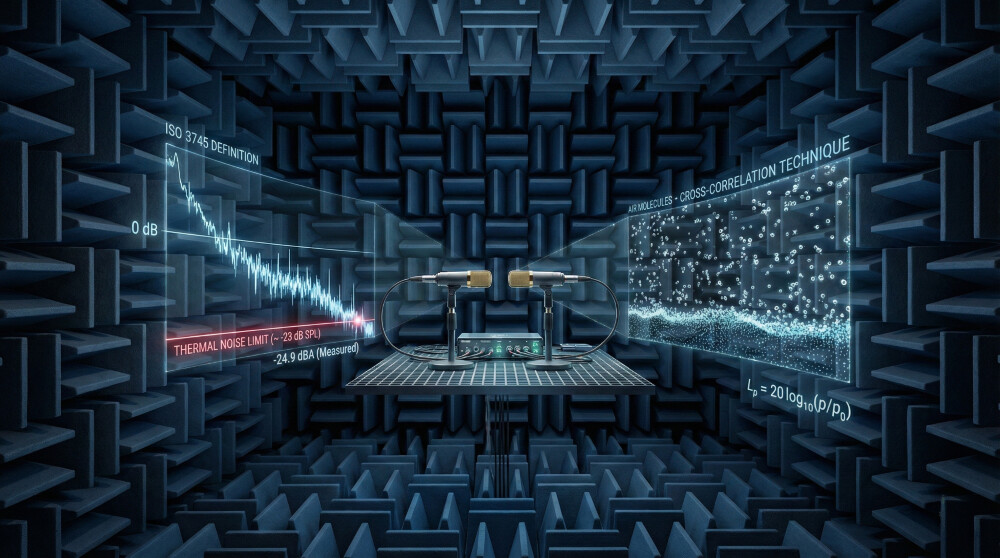

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.