Technical Column

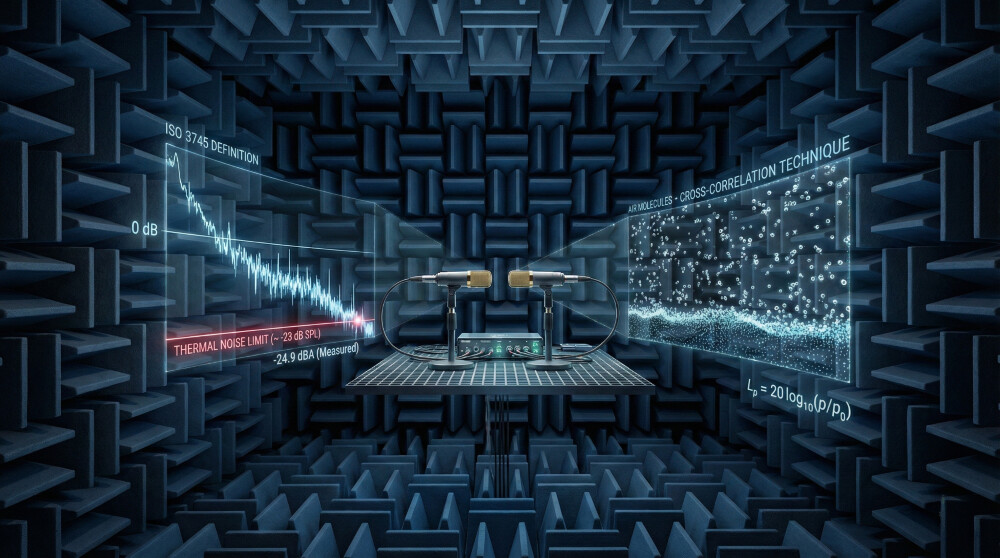

Non-Invasive Acoustic Testing for Sealed Devices — Inspecting Internal Sounds from Outside with AEB × HBK Sensors —

Aug 16, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Non-Invasive Acoustic Testing for Sealed Devices — Inspecting Internal Sounds from Outside with AEB × HBK Sensors —

Simplified Performance Testing Using Anechoic Box + Sound Level Meter

Introduction: How Do You Measure Sounds You Can’t Reach?

Many modern devices—from smart speakers to sealed sensors—generate internal sounds that must be evaluated for quality assurance.

However, opening the enclosure or placing sensors inside is often not possible due to:

- Waterproofing or dustproofing requirements

- High-voltage or sensitive internal circuitry

- Production constraints in mass testing environments

The solution: acoustic inspection from the outside, using a controlled environment and precision measurement tools.

System Overview: AEB × HBK for External Acoustic Sensing

| Component | Description |

|---|---|

| Measurement Environment | AEB (Anechoic Box): Blocks environmental noise and reflections |

| Sensors | HBK Free-Field Microphones + LAN-XI front-end |

| Target Products | Sealed enclosures, potted modules, water-resistant electronics |

| Analysis Software | HBK PULSE / BK Connect for FFT, comparison, and anomaly detection |

This setup allows for stable, repeatable measurements of internal acoustic behavior, without opening the device.

Applications and Use Cases

- Detecting abnormal resonance or buzzing inside an enclosure

- Identifying loose components or vibrating panels without physical access

- Monitoring back-side cavity behavior in speaker modules

- Checking for air leakage or mechanical misalignment via acoustic patterns

- Comparing frequency signatures across multiple units for consistency

Key Advantages

| Non-invasive | No need to open, disassemble, or connect to internal points |

|---|---|

| Consistent | High repeatability thanks to AEB’s quiet, reflection-free space |

| Quantifiable | Recordable FFT data, usable for production QC logging |

| Flexible | Suitable for development, incoming inspection, and aging tests |

Ideal for

- Bluetooth speakers, wireless modules, and IoT devices

- Medical devices with sealed or sterilized casings

- Manufacturers of acoustic or structural enclosures

- Engineering teams analyzing changes caused by design modifications

Customization & Integration Support

- Custom AEB sizing for your device portfolio

- HBK microphone and range selection based on acoustic target

- Threshold-based NG/OK logic with spectrum overlay comparison

- Integration with automation (PLC, barcode scanning, etc.)

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.