Technical Column

Powertrain NVH Testing for EV and Mobility Applications — Multiaxial Measurement of Torque, Vibration, and Noise with VSAC × HBK Sensors —

Aug 1, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Powertrain NVH Testing for EV and Mobility Applications — Multiaxial Measurement of Torque, Vibration, and Noise with VSAC × HBK Sensors —

VSAC + Pass-by Noise System and Related Products

Introduction: The EV Challenge—It’s Too Quiet

Electric vehicles (EVs) are remarkably quiet compared to internal combustion engines.

But this silence creates new challenges: even minor noise and vibration issues stand out, making traditional NVH testing insufficient.

Accurate evaluation now requires high-resolution measurement in an acoustically optimized environment.

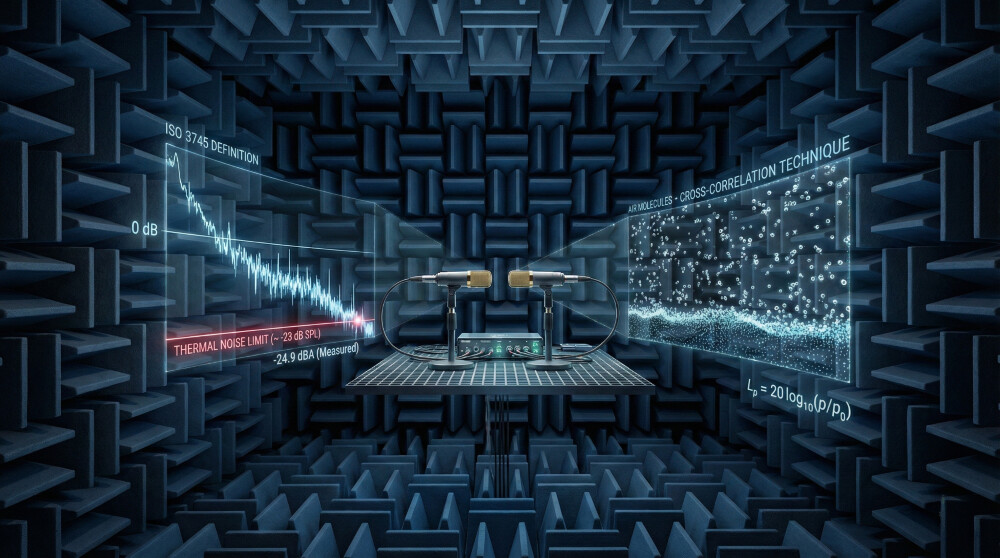

Why Choose a VSAC (Vehicle Semi-Anechoic Chamber)?

Sonora’s VSAC is a specialized chamber designed for EV powertrain and mobility NVH testing. It offers several advantages:

Key Features:

Hybrid Isolation + Absorption Structure

Blocks structure-borne noise from tires or test benches while minimizing airborne reflections.

Full Integration with Chassis Dynos & Drive Units

Ideal for dynamic noise & torque fluctuation analysis under real-world simulation.

Sync with HBK Measurement Systems

Enables synchronized data capture across sound, vibration, and torque channels.

Example Configuration: EV Drive Unit NVH Testing

| Parameter | System Setup |

|---|---|

| Sound | HBK Free-Field Microphones + PULSE or BK Connect |

| Vibration | Triaxial Accelerometers + LAN-XI Front End |

| Torque & Speed | Non-contact Torque Sensor + Motor Control Integration |

→ Data can be synchronously logged, FFT-analyzed, and compared on a unified timeline.

Typical Evaluation Targets

- Detecting resonance shifts under torque fluctuation

- Frequency-domain analysis of motor shaft and inverter noise

- Noise behavior during acceleration/deceleration transitions

- Comparing NVH profiles based on component stiffness or fastening methods

This system allows manufacturers to balance acoustic comfort with drive control strategy in a measurable, data-driven way.

Consultation & Custom Integration

- VSAC design for EV drive unit or chassis-level NVH testing

- Full HBK sensor suite integration and selection support

- Safety and ventilation design for dyno-equipped chambers

- Support for ISO-compliant noise regulation measurements

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.