Technical Column

Acoustic Power Measurement by the Sound Intensity Method

May 26, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Acoustic Power Measurement by the Sound Intensity Method

Acoustic Power Measurement

When measuring acoustic power using the sound intensity method, it becomes possible to perform measurements even near machinery or in environments with steady background noise.

This method is very straightforward: the acoustic power is obtained by multiplying the average normal sound intensity over the measurement surface by the surface area.

The first step is to define this virtual measurement surface.

As long as there are no other sound sources or absorbing materials inside the defined measurement surface, its shape can be arbitrary.

The floor is assumed to reflect all sound perfectly and is therefore not included in the measurement surface.

Theoretically, the distance of the measurement surface from the sound source does not affect the results.

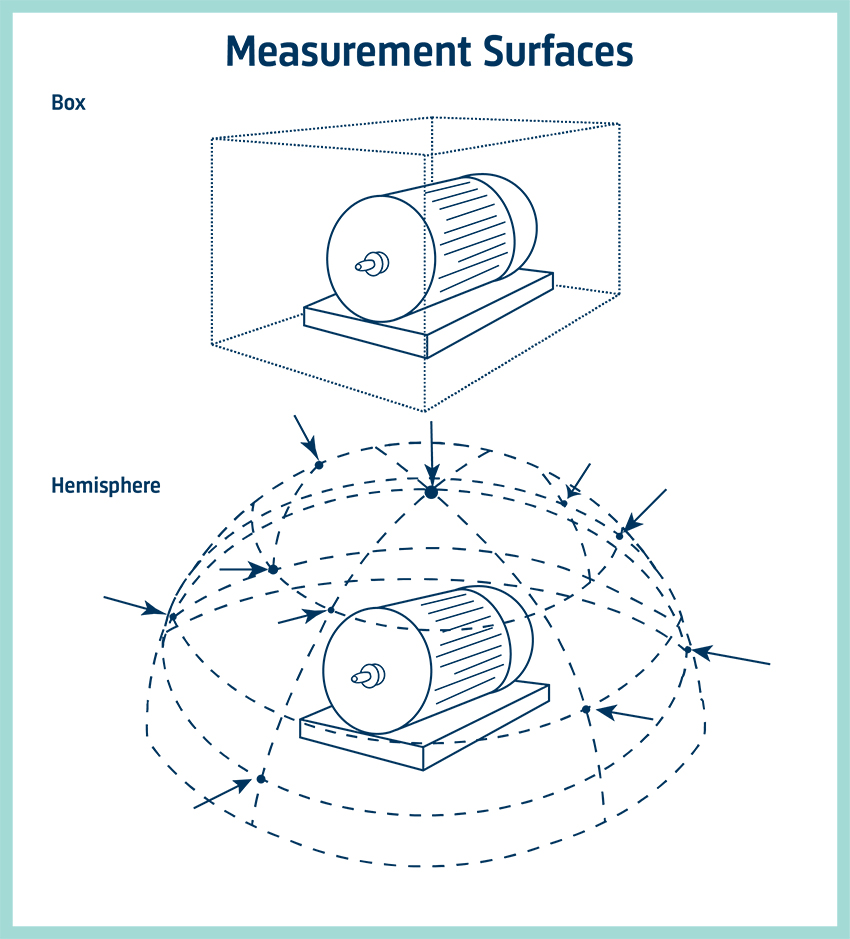

Two examples are shown below.

Rectangular Box

The shape and size of the measurement surface can be arbitrary.

A rectangular box is easy to define and, because of its flat surfaces, makes it simple to average the intensity over each plane.

The partial acoustic power from each surface is calculated individually and then summed.

Hemisphere

Using a hemispherical measurement surface minimizes the number of required measurement points.

In a free-field environment with an omnidirectional source, the intensity is uniform at all points on the hemisphere.

Spatial Averaging

Once the measurement surface is defined, the normal component of the intensity relative to the surface must be measured and spatially averaged.

The measurement surface can be defined physically using a grid, or simply by specifying distances from a reference point.

ISO 9614 consists of three parts, each defining a different measurement method:

- Part 1: Averaging at discrete points

- Part 2 and Part 3: Averaging through scanning across the measurement surface

- Part 3: Additional requirements apply for certain measurement environments

Averaging at Discrete Measurement Points (Discrete-Point Method)

In this method, the measurement surface is divided into small segments, and individual measurements are taken at each segment.

The measurement points are usually arranged in a grid pattern.

You can use rulers or tape measures, but creating a guide using string or wire is also effective.

By averaging the results and multiplying by the area, the total acoustic power for the entire measurement surface is obtained.

Neither method is perfect for every situation; in some cases, both methods can be valid.

The scanning method offers a closer approximation to continuous spatial integration and may provide more accurate results, but it requires moving the probe at a constant speed and covering the measurement surface evenly.

On the other hand, the discrete-point method offers excellent reproducibility.

When repeated measurements are required, both methods can be easily automated, improving precision.

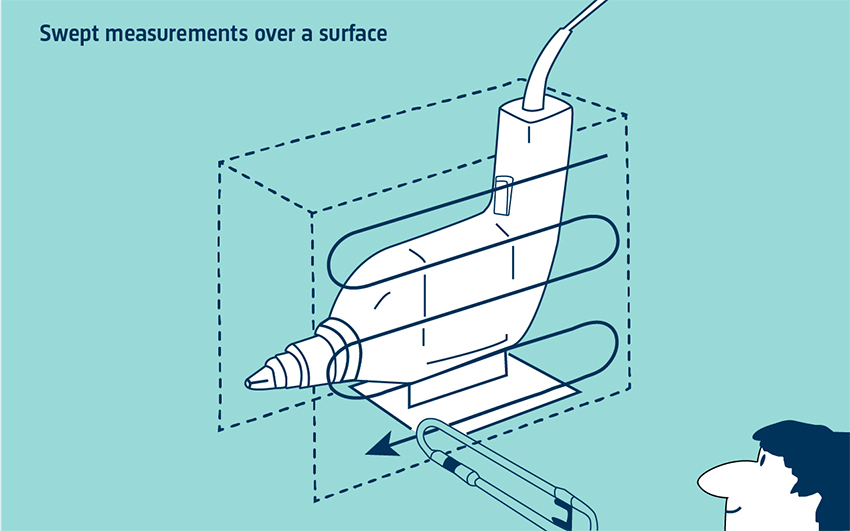

Scanning the Measurement Surface (Scanning Method)

Using an appropriate averaging time, the probe is moved across the measurement surface much like painting the surface.

This produces a single value for the spatially averaged intensity.

Multiplying this value by the surface area gives the acoustic power from that surface.

The acoustic powers from all measurement surfaces are then summed.

Latest Posts in Technical Column

-

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight— -

2025.10.20

End-of-Line Acoustic Testing — Quantifying Quietness in Mass Production —

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.