Technical Column

Acoustic Intensity Probe

May 26, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Acoustic Intensity Probe

Acoustic Power Measurement

An acoustic intensity probe consists of two microphones mounted face-to-face with a spacer positioned between them.

This configuration has been found to offer better frequency response and directional characteristics compared to side-by-side, back-to-back, or face-to-face arrangements without a spacer.

There are three types of spacers available — 6 mm, 12 mm, and 50 mm — which maintain a fixed distance between the microphones.

The choice of spacer depends on the frequency range to be covered.

Directivity Characteristics

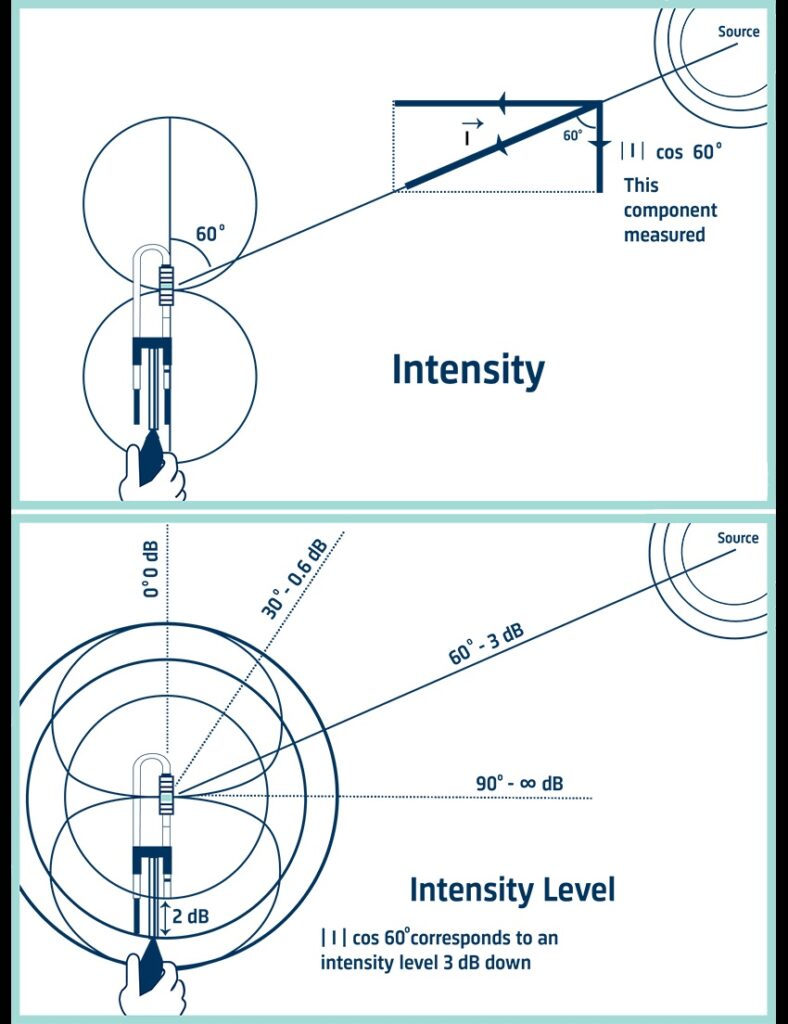

The directivity pattern of an acoustic intensity analysis system appears as a figure-eight shape in a planar view, which is referred to as a cosine characteristic.

This characteristic arises from the design of the probe and the calculations performed by the analyzer.

Since sound pressure is a scalar quantity, transducers used for sound pressure measurement must respond equally to sound from all directions — that is, they must be omnidirectional.

In contrast, acoustic intensity is a vector quantity.

With a two-microphone probe, the system does not measure the full vector but instead measures the single directional component along the axis of the probe.

A complete vector is composed of three mutually perpendicular (90° to each other) components, one for each coordinate axis.

When sound is incident at a 90° angle relative to the probe axis, there is no difference between the sound pressure signals from the two microphones.

As a result, there is no component along the probe axis, the particle velocity becomes zero, and thus the acoustic intensity also becomes zero.

In contrast, when sound is incident at an arbitrary angle θ relative to the axis, the intensity component along the axis decreases by a factor of cosθ.

This reduction leads to the cosine directivity characteristic of the probe.

Latest Posts in Technical Column

-

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight— -

2025.10.20

End-of-Line Acoustic Testing — Quantifying Quietness in Mass Production —

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.