Technical Column

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers

Nov 7, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers

Acoustic Power Measurement

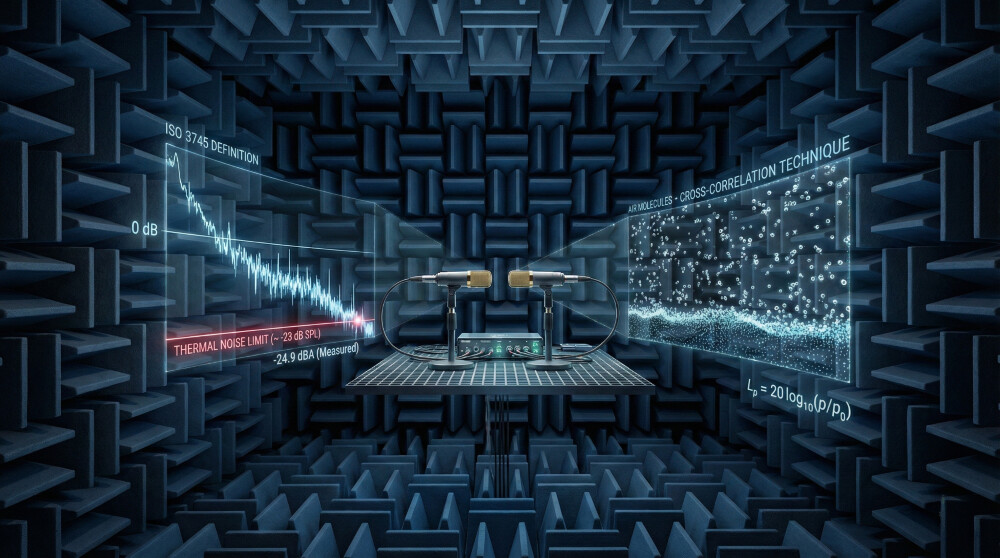

Introduction

When measuring sound pressure levels in an anechoic chamber, the most fundamental assumption is the Inverse Square Law—that sound energy decreases by 6 dB each time the distance doubles.

However, this rule only holds in an ideal free-field.

In real anechoic environments, factors such as absorption limits, sound source size, and frequency cause deviations from ideal conditions.

This article explains how to design and verify the region where the Inverse Square Law is valid, also known as the K₂ correction zone, according to ISO 3745 and related standards.

What Is the Inverse Square Law?

For a point source in a free field, the sound pressure level decreases as:

where LpL_pLp is the sound pressure level at distance rrr, and Lp1L_{p1}Lp1 is the level at a reference distance r1r_1r1.

The region where this relationship holds is called the Inverse Square Law Zone.

Why It Fails in Real Anechoic Rooms

Even high-performance anechoic chambers are not perfect free fields.

Deviations occur due to:

- Limited low-frequency absorption

- Extended or directional sound sources

- Measurement within the near field

- Residual reflections from walls or structures

Therefore, determining where the law actually holds is critical for reliable measurements.

Defining the Valid Measurement Distance

According to ISO 3745 and JIS Z 8732, the transition from near field to far field is given by:

where DDD is the maximum source dimension and λ\lambdaλ is the wavelength.

Larger sources and lower frequencies require proportionally greater distances to maintain free-field conditions.

Practical Design Considerations

To achieve a valid inverse-square region, both the chamber and the test setup must be designed carefully:

- Adequate low-frequency absorption (below 200 Hz)

- Proper source–microphone distance (typically 1–2 m)

- Symmetrical microphone arrangement

- Obstacle-free measurement axis

Meeting these design criteria ensures compliance with ISO 3745 Class 1 or Class 2 accuracy standards.

Understanding K₂ Correction

In practice, deviations from the ideal law are quantified as K₂ values, representing the difference between theoretical and measured sound decay.

K₂ should be within ±1.5 dB (Class 1) or ±2.5 dB (Class 2).

A stable K₂ indicates both acoustic integrity of the chamber and reliability of measurement results.

Conclusion: Designing Distance for Accuracy

An anechoic chamber is not merely a “quiet room.”

It is a precisely engineered environment that enables accurate acoustic measurement.

Designing the correct Inverse Square Law zone means designing for trustworthy data—linking architectural silence with metrological precision.

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.