Technical Column

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing —

Nov 13, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing —

Introduction

Field sound measurements used to rely on large, stationary laboratory systems.

Today, portable microphones, wireless recorders, and cloud-connected software enable laboratory-grade accuracy directly on site.

This article explores the technological foundations that allow modern mobile acoustic instruments to achieve reliable, ISO-compliant results in building and environmental sound measurements.

The Challenge: Portability vs. Precision

Field testing faces inherent limitations:

- Restricted space and power availability

- Weather and environmental variability

- Background noise and interference

- Clock synchronization errors across devices

Balancing mobility and repeatability requires both robust hardware and intelligent data synchronization.

Technological Advances in Mobile Measurement

Modern portable analyzers now integrate laboratory-level capabilities:

| Feature | Description |

|---|---|

| Digital calibration | Automatic sensitivity and frequency compensation |

| GPS time synchronization | Sample-accurate alignment across multiple units |

| 24-bit A/D conversion | Wide dynamic range for precise low-level sound |

| App connectivity | Integrated acquisition, analysis, and reporting |

These developments enable compliance with ISO 16283 (Building Acoustics) and ISO 1996 (Environmental Noise) even in field conditions.

Field Calibration and Verification

Temperature and humidity affect microphone behavior.

Therefore, on-site calibration is essential.

Modern systems incorporate portable calibrators with automatic sensitivity check and metadata recording, ensuring reliable traceability and confidence intervals in data analysis.

Synchronization and Multi-Point Measurement

Multi-microphone tests require time synchronization accuracy.

Current systems achieve sub-millisecond synchronization using Wi-Fi or GPS, critical for evaluating parameters such as RT60 or level differences.

Cloud-based synchronization also allows remote teams to access and compare data from multiple sites simultaneously.

Data Integrity and Automated Analysis

Advanced mobile platforms combine traceability with automation:

- Automatic recording of conditions, location, and time

- AI-assisted filtering of invalid or noisy data

- Cloud-based reporting and sharing

The result: field data that can be used directly for research, validation, or compliance testing.

Conclusion: Turning the Field into a Laboratory

The boundary between laboratory and field testing is disappearing.

With mobile acoustic technology, the site itself becomes the test environment, offering precision, traceability, and speed.

Accurate field measurement is no longer a compromise—it is the new standard of sound engineering.

Latest Posts in Technical Column

-

2026.01.29

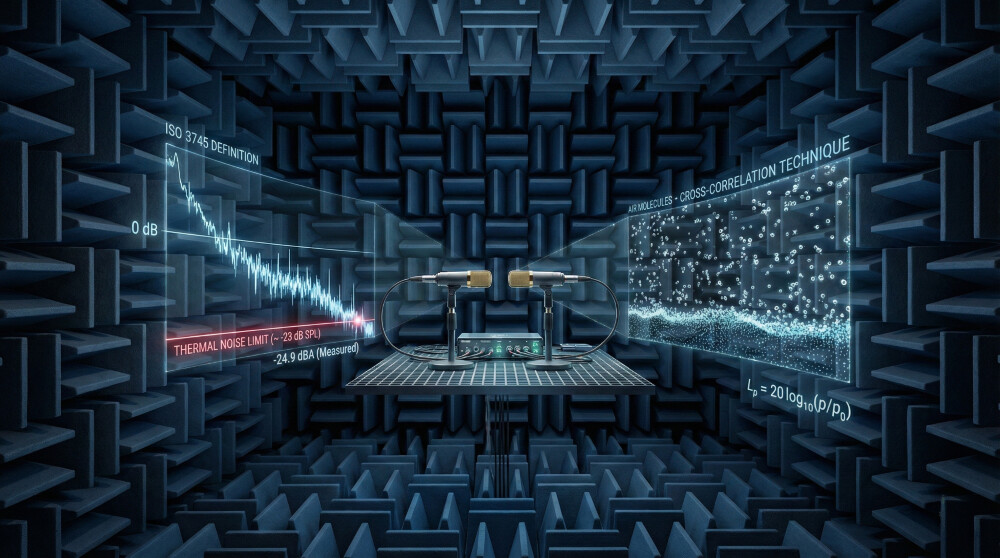

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.