Technical Column

What Makes an Anechoic Chamber Suitable for ANSI-Compliant Acoustic Testing?

May 23, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- What Makes an Anechoic Chamber Suitable for ANSI-Compliant Acoustic Testing?

Electroacoustic Measurement

Moritani’s Total Acoustic Measurement Solution Featuring HBK × Sonora

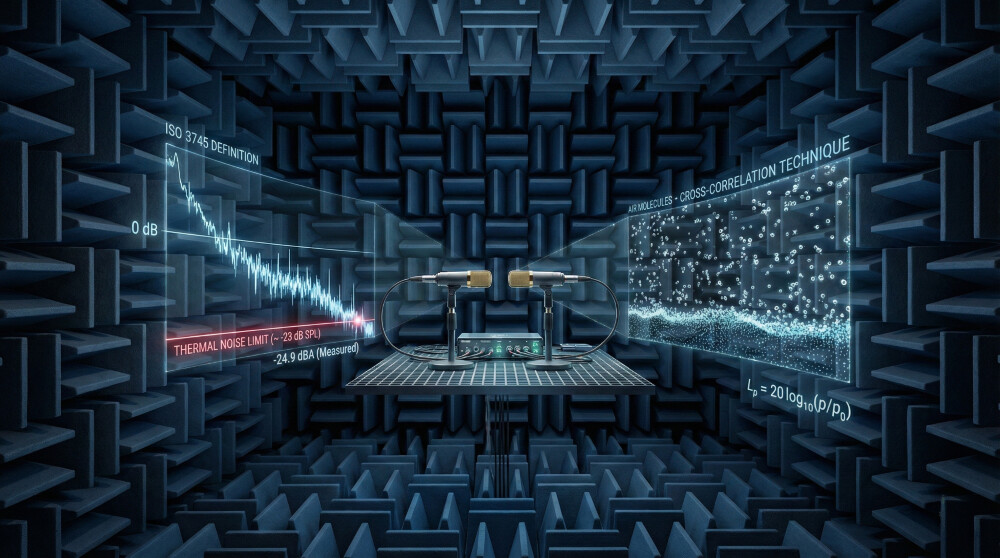

Accurate sound power measurement is essential for quantifying product quietness and overall quality. Standards such as ANSI/ASA S12.55 and S12.54 (aligned with ISO 3745 and ISO 3744, respectively) require the test environment to support a free-field condition, where sound attenuates in accordance with the inverse square law.

At Moritani Corporation, we provide comprehensive acoustic testing solutions by integrating the measurement expertise of HBK (Hottinger Brüel & Kjær) with the chamber design innovations of Sonora Technology, a pioneer in anechoic room engineering.

ANSI-Compliant Test Spaces — Ensuring the Inverse Square Law

ANSI/ASA S12.55 specifies that the inverse square law must hold within the test volume—meaning that the sound pressure level decreases in proportion to the square of the distance from the source. This principle verifies the validity of a free-field condition, essential for accurate acoustic power level evaluation.

To meet this requirement, we recommend using HBK’s Type 4292-L omnidirectional 12-face speaker in combination with the Type 2734 power amplifier, ensuring a broadband, uniform sound field.

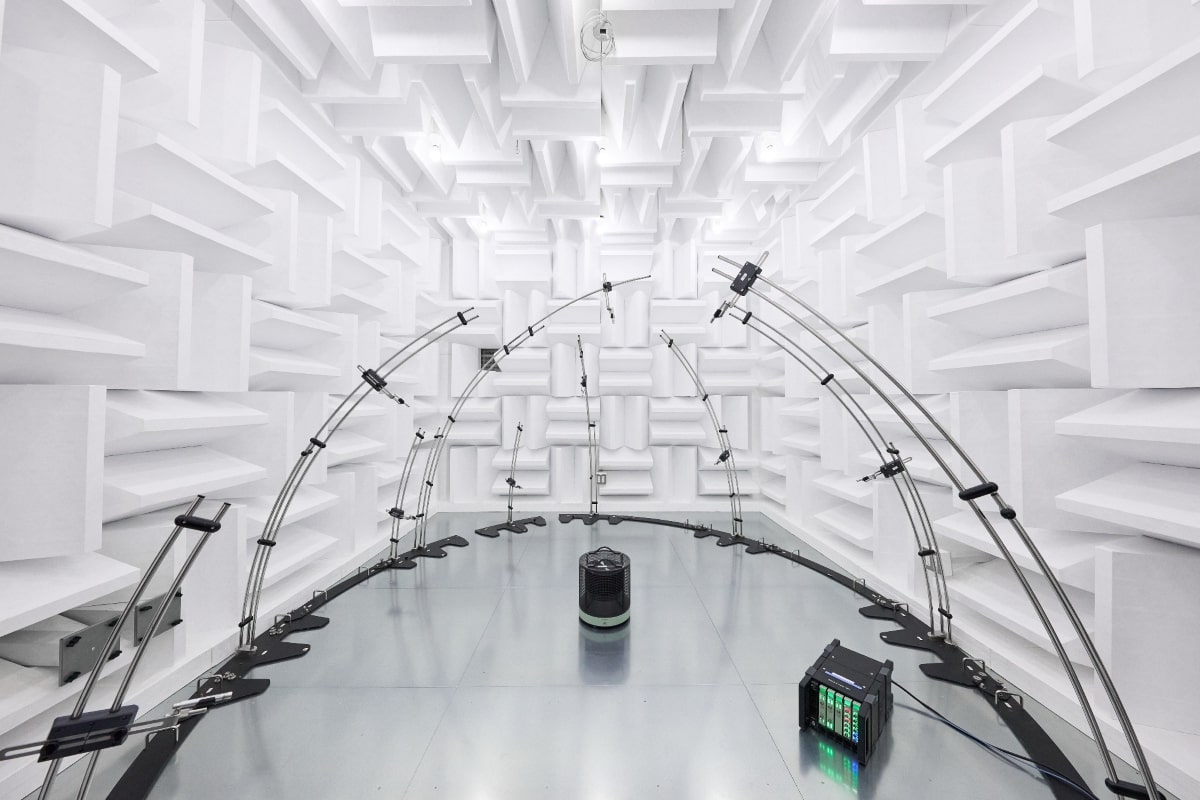

Precision-Controlled Spaces by Sonora Technology

Sonora’s anechoic chambers are meticulously engineered to meet ISO/ANSI requirements. Their proprietary BFW (Broadband Fractal Wedge) absorption system achieves low cut-off frequencies and wideband absorption, allowing free-field conditions to extend beyond the central zone of the chamber.

In semi-anechoic configurations (compliant with ISO 3744), Sonora chambers are designed to maintain K₂ ≤ 4 dB, ensuring valid measurements in more practical, floor-reflective environments.

Recommended Configuration (ISO 3745 / ANSI S12.55)

| Element | Specification |

|---|---|

| Chamber | Sonora MFAC or SPAC anechoic chamber |

| Absorbers | BFW sound-absorbing wedges |

| Sound Source | HBK Type 4292-L + Type 2734 Amplifier |

| Microphone | HBK Type 4189 |

| Analysis Software | BK Connect + Sound Power Module |

This configuration supports precision testing with K₂ ≤ 0.5 dB, satisfying strict ANSI/ISO requirements for sound power level measurements.

One-Stop Solution for Acoustic Test Environments

Struggling with mismatched equipment and test room design? Facing issues with K₂ verification?

Moritani offers full-cycle solutions—designing and constructing the test chamber, selecting and installing equipment, and verifying system performance. Backed by HBK × Sonora technologies, we ensure high-precision, standards-compliant acoustic testing environments.

Contact Moritani

Whether you’re evaluating new test equipment, setting up an anechoic space, or seeking technical consultation, we’re here to help.

On-site visits and online consultations are available.

[Contact Us → Moritani Corporation, Tokyo Headquarters – Machinery Division 2]

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.