Technical Column

What Is the K₂ Correction Factor? — The Importance of Correcting Measurement Errors Caused by Second Harmonic Distortion

May 23, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- What Is the K₂ Correction Factor? — The Importance of Correcting Measurement Errors Caused by Second Harmonic Distortion

Acoustic Power Measurement

Introduction

Achieving high-precision data in acoustic measurements requires attention to one often overlooked but critical parameter: the K₂ correction factor. This article explains what the K₂ correction is, why it matters, and how it is applied in real-world acoustic evaluations.

What Is the K₂ Correction Factor?

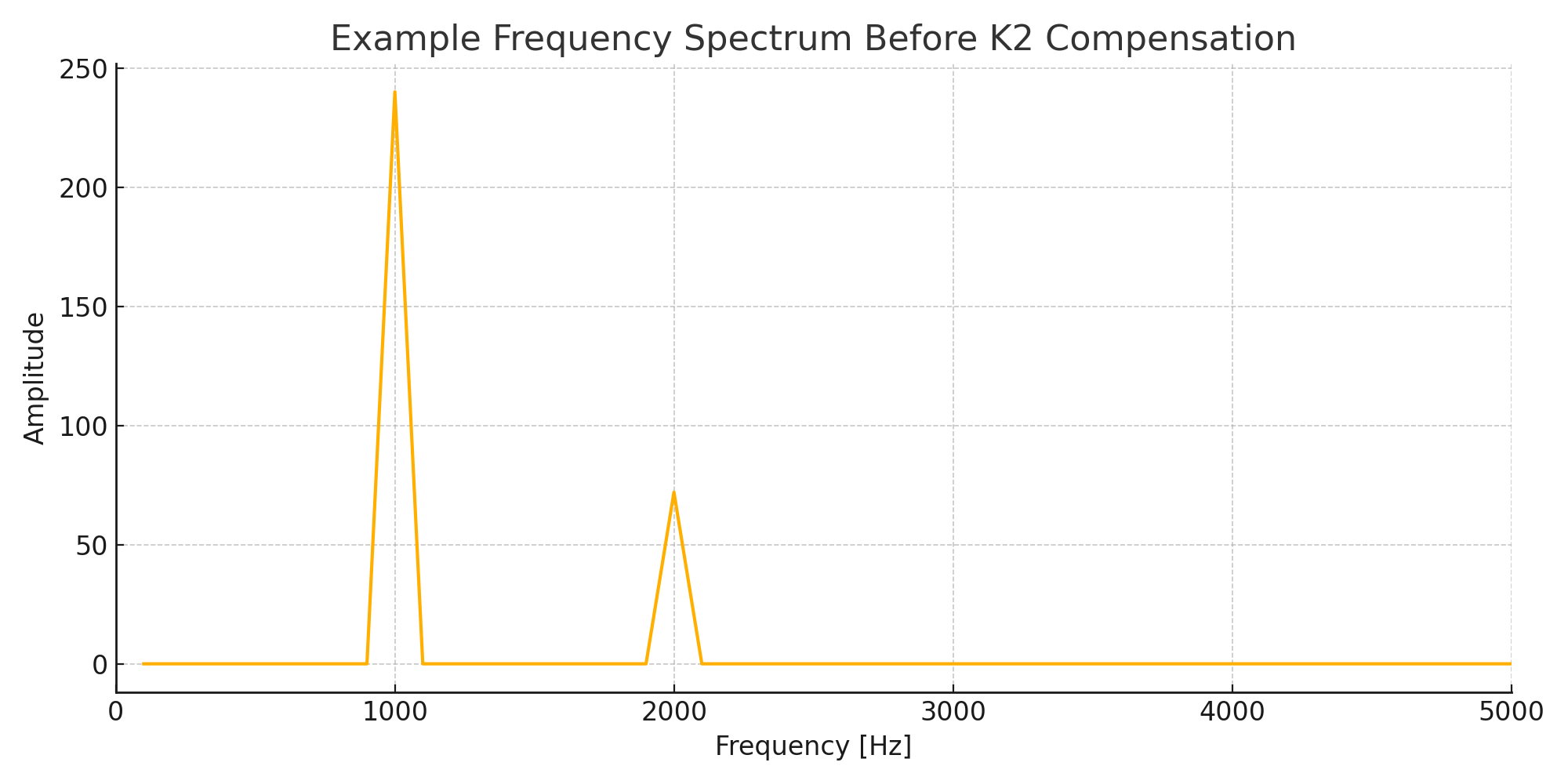

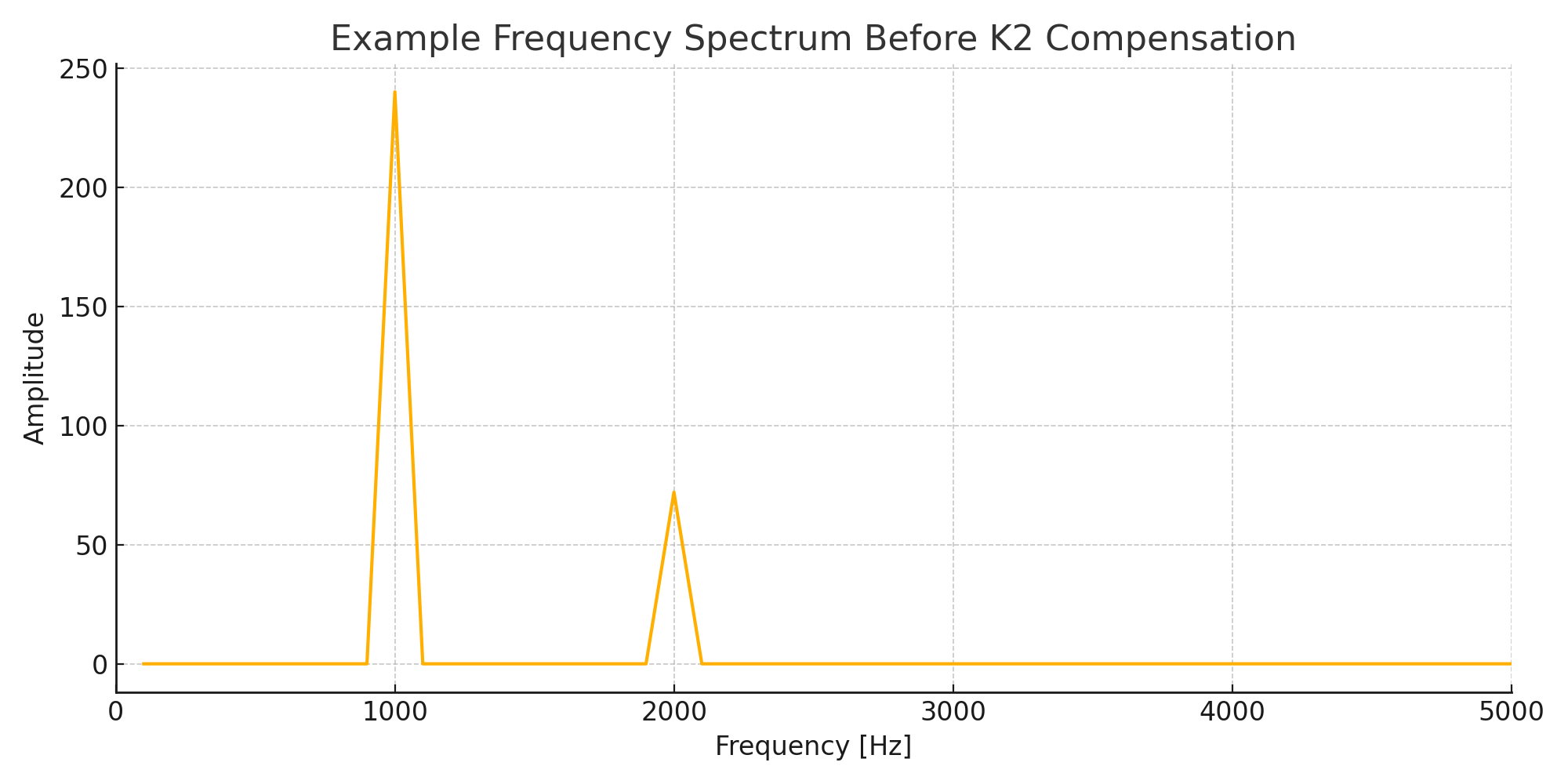

The K₂ correction factor is used to correct measurement errors caused by second harmonic distortion (2nd-order harmonics).

In theory, when an audio signal (such as a pure sine wave) is reproduced by a speaker, only the intended frequency should be emitted. However, due to non-linearities in audio equipment, harmonic components—frequencies that are integer multiples of the original signal—often appear.

Among these, second-order harmonics (2f₀) can significantly distort sound pressure measurements and frequency response analysis, leading to incorrect evaluations.

When Is K₂ Correction Especially Important?

K₂ correction is crucial in the following use cases:

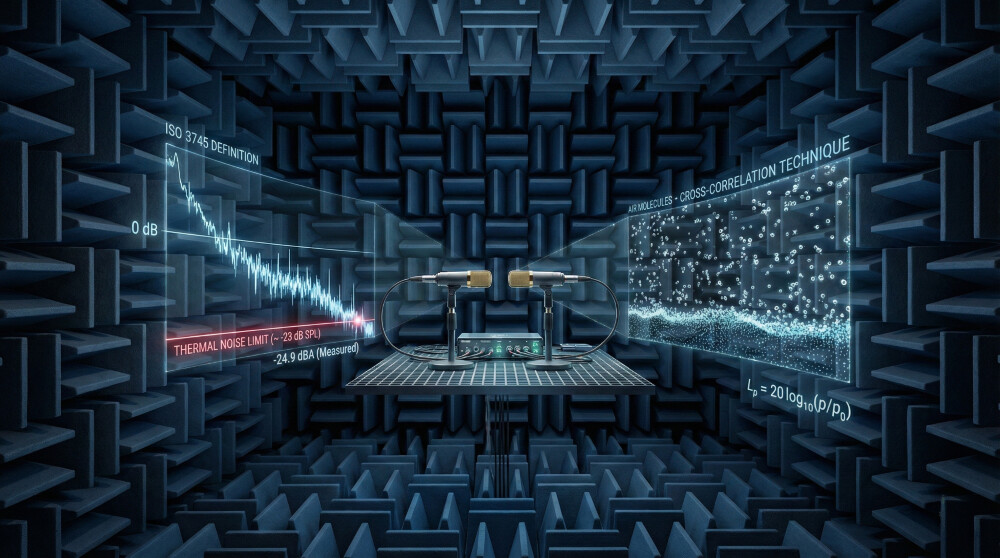

- Speaker testing in anechoic or semi-anechoic chambers

- In-vehicle acoustic tuning and NVH validation

- Architectural acoustic testing of sound-absorbing materials

- Measurement of headphones and earbuds (where signal-to-noise ratio is low)

- Design of high-end audio equipment, such as amplifiers and precision loudspeakers

Furthermore, certain ISO and JIS testing standards explicitly require the evaluation and correction of K₂ components, making it a critical part of any credible measurement process.

Why Is K₂ Correction Necessary?

For example, during measurement, you may input a 1 kHz tone to a speaker, but due to non-linearity, a 2 kHz harmonic may also be emitted unintentionally. This second harmonic can be picked up by the microphone and falsely interpreted as part of the actual signal, introducing incorrect peaks or dips in the frequency response curve.

By applying K₂ correction, the influence of this unwanted harmonic is mathematically removed, allowing for an acoustic profile that more accurately reflects the true characteristics of the product.

How Is K₂ Correction Applied?

K₂ correction typically follows these steps:

- 1. A sweep signal (e.g., 1 Hz to 20 kHz) is played through the DUT (Device Under Test)

- 2. The output signal is captured using a calibrated microphone

- 3. The 2nd-order harmonic components (2 × f₀) are isolated and quantified

- 4. Measurement software applies the K₂ correction to remove the distortion effect

Most advanced measurement systems—such as those from HBK (Brüel & Kjær), Audio Precision, or MLSSA—come with built-in K₂ correction functions. These tools also allow comparison between raw and corrected data.

For instance, applying K₂ correction can result in up to 3 dB of difference in the 200 Hz to 2 kHz range, which is significant in precision acoustic testing.

Summary

The K₂ correction factor is an essential part of any high-fidelity acoustic measurement. By compensating for second harmonic distortion, engineers and developers can obtain a true representation of a product’s sound performance.

Whether you’re evaluating a quiet HVAC system or designing a high-end audio speaker, understanding and applying K₂ correction is a critical step toward accurate acoustic analysis.

At Moritani Corporation, we support K₂ correction workflows through our HBK × Sonora solution packages, including compliant chambers, calibrated microphones, and software-based harmonic analysis.

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.