Technical Column

Why Build Your Own Acoustic Test Facility? SONORA × HBK: Designing Acoustic Spaces That Accelerate Innovation

Jul 9, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- Why Build Your Own Acoustic Test Facility? SONORA × HBK: Designing Acoustic Spaces That Accelerate Innovation

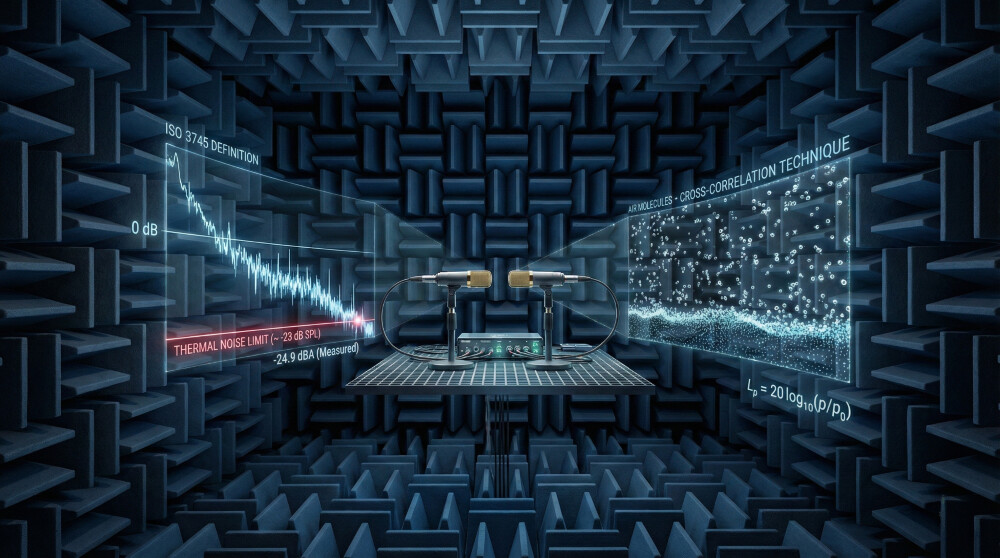

Acoustic Power Measurement

Beyond Measurement: Acoustic Labs That Accelerate Development

Acoustic performance is becoming increasingly critical across a wide range of industries—from actuators and precision devices to telecommunications and medical equipment.

As a result, the question of whether to establish an in-house acoustic testing facility is becoming central to many companies’ R&D strategies.

The growing adoption of anechoic and semi-anechoic chambers reflects their value not just for testing, but for accelerating development, enhancing data security, and increasing technical competitiveness.

Benefit 1: Faster Development Through Immediate Testing

Owning acoustic testing equipment—such as anechoic chambers, AEBs (Anechoic Boxes), and sound level meters—offers the key advantage of instant measurement.

- Evaluate acoustic performance immediately after prototyping → Begin design improvements the same day

- Dedicated use by internal teams → No need to coordinate with external labs

- Project-specific control → Flexible operations without bottlenecks

For example, you can begin by narrowing down acoustic design directions using an AEB, then expand into power level and sound quality testing using a SPAC (Sound Power Anechoic Chamber) or VSAC (Vehicle Semi-Anechoic Chamber).

Adding HBK’s Type 4204 reference sound source, LAN-XI modules, and the PULSE analysis system enables full compliance with ISO 3744/3745 and allows for objective, high-speed measurement workflows.

Benefit 2: Combining Data Security and Repeatability

In the early stages of development, both product designs and acoustic data are highly sensitive.

In-house testing significantly reduces the risk of information leakage, which is hard to avoid when outsourcing.

- Internal-only testing → Substantially lower risk of information loss

- Consistent test conditions → High measurement repeatability

- Engineers hear and analyze directly → Enhanced sensitivity and acoustic insight

Using HBK’s precision microphones (e.g., Type 4189), signal generators, and omnidirectional sound sources ensures accurate and reliable measurements.

Benefit 3: Skill Development and Knowledge Retention

An internal acoustic lab is not just a test site—it’s a learning platform for engineers.

- Hands-on testing → Engineers gain intuitive understanding of sound and design

- Accumulated test cases → Valuable design knowledge is retained in-house

- Cross-functional usage → Fosters a sound-aware culture within the organization

In particular, EAACs (Electroacoustic Anechoic Chambers) used for microphone and speaker testing can be paired with HBK’s signal processing equipment to maximize training impact.

Key Considerations and Solutions

△ Cost of Setup and Maintenance

- Large chambers like VSAC require substantial initial investment

- Requires integrated planning of air conditioning, power, and acoustic insulation

△ Operational Management

- Rules for use, scheduling, and data handling must be defined

- Dedicated staff and training costs need to be factored in

△ Aging and Performance Degradation

- Absorptive and shielding materials deteriorate over time

- Regular K2 measurements and diagnostics are essential to maintain performance

- Upgrading to SONORA’s BF Series (BFW/BFB/BFP) helps ensure long-term accuracy and efficiency

ISO 3744 defines K2 ≤ 4 dB as a realistic performance target. HBK measurement systems are ideal for K2 evaluation and maintenance.

From “Testing Space” to “Creation Space”

Bringing acoustic testing capabilities in-house is not just about building a lab—it’s about creating strategic infrastructure that drives product development.

- Choose the right chamber type (VSAC / SPAC / AEB) for your application

- Design holistically: acoustics, shielding, HVAC, and workflow movement

- Focus on usability, maintainability, and learnability from the outset

The Future of Development, Built by SONORA × HBK

SONORA’s chambers are designed not only for performance but for integrated development and educational usability.

Paired with HBK’s advanced measurement systems, your facility can meet global standards in acoustic testing.

- Modular, relocatable MSAC and AEB solutions

- High-performance, space-efficient BF Series absorbers

- Total solutions with HBK instruments that meet ISO/JIS standards

Measure more freely.

Develop more quickly.

Understand sound more deeply.

Your first step starts with building your own space to measure sound.

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.