Technical Column

Indoor Coast-by

May 23, 2025

Standard for Indoor Noise Testing of Tires Using a Drum Test Machine

In 2023, ISO 20908:2023 was introduced as a new method for indoor testing of tire noise emissions.

“Tyre sound emission test. Methods of drum”

Compared to the existing outdoor measurement method ISO 13325, this ISO standard appears to be the first edition specifically for indoor measurements.

Similar to ISO 362-1, 362-2, and 362-3, which measure vehicle pass-by noise, this new standard was established to enable testing that was previously limited to outdoor environments to now be conducted indoors.

There is a growing trend toward performing vehicle noise measurements indoors through “indoor pass-by” methods, as opposed to traditional outdoor test tracks.

Outdoor tests have been subject to weather conditions, such as rain and strong winds, which restricted testing to specific times. However, with the introduction of ISO 20908, efficient and flexible indoor testing has become possible.

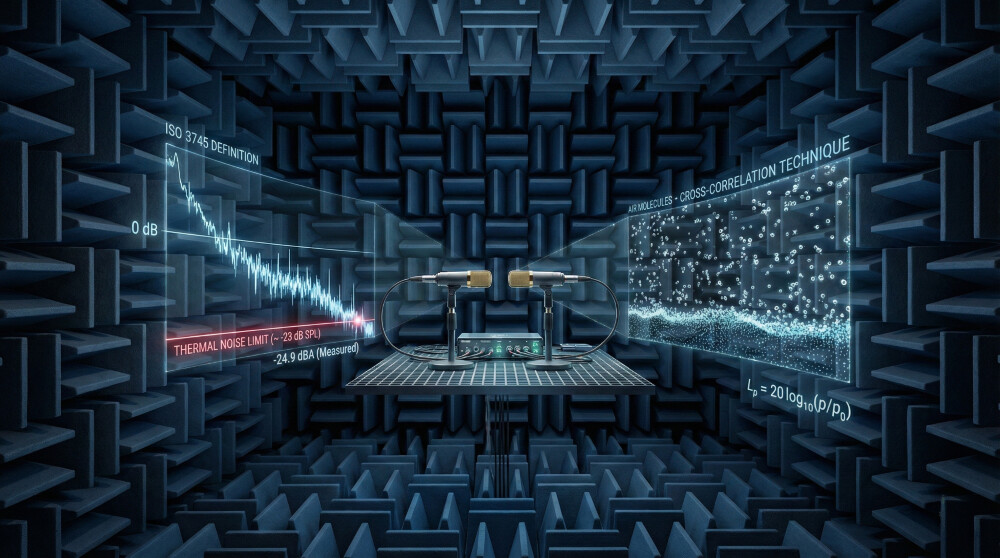

That said, constructing an indoor testing facility requires a wide range of equipment, including a drum system, a semi-anechoic chamber, and precise temperature control.

Additionally, it is necessary to properly address the sound components of rolling noise based on ISO 10844.

As a manufacturer of anechoic chambers, we are capable of proposing facility designs that meet the required specifications, including temperature-controlled environments and microphone array layouts based on the inverse square law.

Temperature control is managed in a manner similar to a thermal chamber, with insulation applied to the walls, ceiling, floor, and doors of the anechoic room, combined with an advanced HVAC system.

While the temperature ranges required by ISO 362-3 and ISO 20908 may differ, the measurement methods based on the inverse square law are similar to those defined in ISO 362-3.

Furthermore, considering the relationships with other standards, the newly established “Indoor Coast-by” evaluation method now enables quantitative assessment of tire coast-by noise at any time.

Drawing on our extensive experience and knowledge, we are committed to designing rooms and measurement systems that comply with these latest standards.

Please feel free to contact us for more information.

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.