Technical Column

The Truth Behind the 0.99 Absorption Coefficient : Understanding Cut-off Frequency and the Performance of Acoustic Wedges

Jun 25, 2025

- HBK × SONORA Acoustic Measurement Solution Official Website

- Technical Column

- The Truth Behind the 0.99 Absorption Coefficient : Understanding Cut-off Frequency and the Performance of Acoustic Wedges

Acoustic Power Measurement

What Does a Sound Absorption Coefficient of 0.99 Really Mean in an Anechoic Chamber?

Have you ever experienced that sensation of your ears “tightening” the moment you enter an anechoic chamber?

This is a sign that almost all sound energy is being absorbed, with virtually no reflections occurring in the space.

This performance is expressed numerically by the sound absorption coefficient of 0.99, meaning that 99% of the sound reaching the wall is absorbed, and only 1% is reflected.

The key element that makes this “near-total absorption” possible is the sound-absorbing wedge, the heart of the anechoic chamber.

The Relationship Between Absorption and Reflection Coefficients

The sound absorption coefficient (α) represents how much of the incident sound energy on surfaces like walls or ceilings is absorbed.

Here, r is the sound pressure reflection coefficient.

For example, if r = 0.1 (10% reflection), the absorption coefficient is:

α=1−r2=0.99\alpha = 1 – r^2 = 0.99α=1−r2=0.99

This means that achieving a coefficient of 0.99 requires suppressing reflected sound to below 10%—a highly demanding condition.

What Is the Cut-off Frequency?

Does the absorption coefficient of 0.99 apply to all frequencies?

The answer is no.

Sound-absorbing wedges have a design parameter called the cut-off frequency, which defines:

The lowest frequency above which the wedge can maintain an absorption coefficient of 0.99.

Sounds below this frequency—such as low-frequency noise under 100 Hz—may penetrate the absorbing material or reflect back into the room.

Why λ/4 Design Is Critical

The most critical factor in achieving the desired cut-off frequency is the length of the wedge.

In most anechoic chambers, wedges are designed based on the quarter-wavelength (λ/4) of the target frequency.

Example:

For 500 Hz:

- Sound speed ≈ 340 m/s

- Wavelength λ ≈ 0.68 m

- λ/4 ≈ 0.17 m (17 cm wedge length)

So, to lower the cut-off frequency, the wedge must be made longer.

A 100 Hz cut-off would require wedge lengths of at least 0.85 meters.

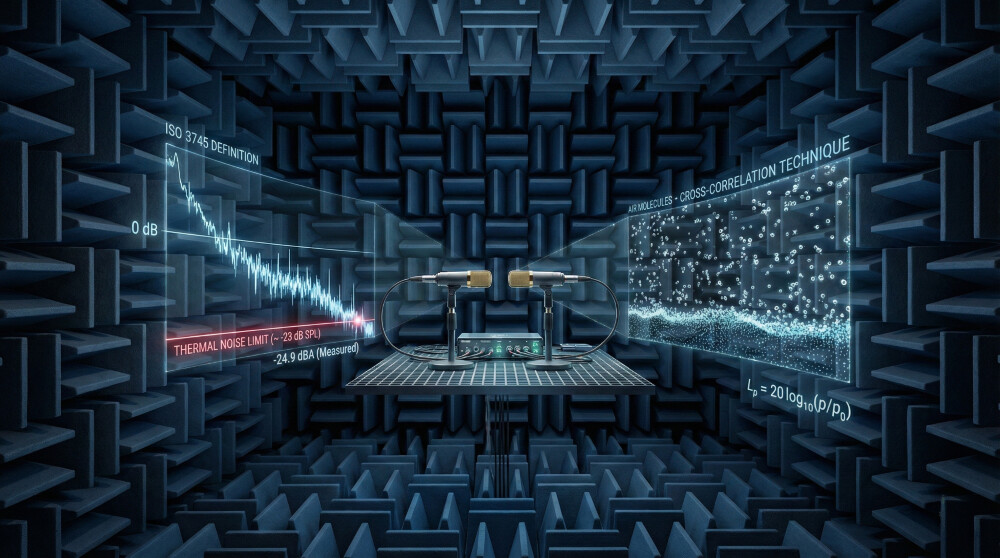

Performance Requirements from ISO and JIS Standards

The older standards, such as ISO 3745:2003 and JIS Z 8732, required an absorption coefficient of 0.99 or higher for the walls and ceilings of anechoic chambers.

However, ISO 3745:2012 removed this specific numeric requirement.

Instead, performance is now judged based on whether the inverse square law is satisfied—i.e., sound pressure decreases in proportion to the square of the distance from the source.

Thus, practical acoustic performance, rather than just the numerical value of 0.99, is emphasized today.

Can a Room Be “Anechoic” with Less Than 0.99?

In some cases, the answer is yes.

Modern designs include “non-tingling” anechoic chambers that use perforated metal panels over glass wool or melamine-based flat absorbers instead of wedges.

Even if their high-frequency absorption falls below 0.99, they can still be certified as anechoic rooms—as long as the inverse square law holds true.

Sonora’s Acoustic Wedges: Exceeding Cut-off Frequency Limitations

Sonora’s BF series (BFW, BFB, BFP) is engineered with advanced acoustic design principles and carefully selected materials to exceed traditional limitations regarding cut-off frequency.

Absorption Based on λ/4 Principles

Each wedge is designed to match λ/4 of the target frequency.

With multi-layered internal structures and precisely controlled air cavities, high absorption is achieved with compact thickness.

Tyvek® Surface Material

The surface of the wedge uses Tyvek®, a nonwoven material known for high water resistance and durability.

Tyvek allows water vapor to pass but blocks liquid water, making it ideal for humid environments.

It also minimizes dust generation and enables easier cleaning and long-term stable performance.

Reference video (starting at 4:00):

Measured and Verified Performance

Sonora does not rely solely on theoretical design.

All products are validated through practical measurements such as inverse square law testing and K2 evaluation.

Full compliance with ISO 3745 and ISO 3744 acoustic testing standards is ensured.

Conclusion: The Real Meaning Behind “0.99”

A sound absorption coefficient of 0.99 is a symbolic benchmark of ideal sound absorption.

Achieving this level of performance requires both λ/4 design precision and cut-off frequency optimization.

Today’s anechoic chambers are evaluated less by numbers and more by actual acoustic behavior.

At Sonora, we provide true free-field environments through absorption wedges precisely designed with both absorption coefficient and cut-off frequency in mind.

Latest Posts in Technical Column

-

2026.01.29

Can We Create “Absolute Silence” on Earth? — An Academic Reading of Anechoic Chambers and Ultra-Low Background-Noise Measurement — -

2025.12.11

The Geometry of Acoustic Design — How Chamber Shape Defines Sound Field Performance -

2025.12.06

Integrated Design of Anechoic Chambers with Auxiliary Equipment — Balancing Silence and Functionality — -

2025.11.30

Modular Semi-Anechoic Chambers — A Flexible Solution for Deployable Acoustic Testing — -

2025.11.25

Measuring Silence: How Anechoic Chambers Support Industrial Quality -

2025.11.18

Designing for Reproducibility — Environmental Stabilization in Acoustic Measurement — -

2025.11.13

The New Generation of Mobile Acoustic Measurement — Field Accuracy for Building and Environmental Sound Testing — -

2025.11.07

The Design Logic Behind the Inverse Square Law Zone in Anechoic Chambers -

2025.10.31

Acoustic Cameras and Anechoic Chambers — Visualizing Silence for Sound Source Analysis — -

2025.10.25

Integrated Acoustic and Vibration Analysis — Designing the Data Flow That Connects Measurement and Insight—

Contact Us

- Contact us by email

-

- Contact us by phone

-

Moritani Shokai

(Machinery Department No. 2, Tokyo Head Office)

Introduction of the Manufacturer

-

Hottinger Bruel & Kjaer

HHBK is a merger of two companies: Brüel & Kjær of Denmark and HBM of Germany.

Brüel & Kjær is one of the world’s leading manufacturers of acoustic and vibration measurement instruments, known as a total measurement chain supplier.Learn more about HBK

-

Sonora Technology Co., Ltd.

Sonora Technology is a leading Japanese manufacturer of industrial anechoic chambers and anechoic boxes.

From design and manufacturing to installation and acoustic performance assurance, Sonora provides fully integrated solutions to build complete acoustic measurement environments from the ground up.Learn more about Sonora

Contact / Request Brochure

For inquiries or consultations regarding the total solutions provided by HBK × Sonora, please feel free to contact us using the Contact button.

If you would like a brochure sent by mail, please use the Request Brochure button.